About Department

Department of Textile Technology was established since 1997 with B.Tech - Textile Technology and well-equipped laboratories, experienced faculty and dedicated staff members to meet the technical manpower needs of the rapidly expanding textile and garment industry by creating industry-ready graduates.Department have PG program M.Tech - Textile Technology and Ph.D - Textile Technology (Full time & Part time) to create a research and startup culture in the area of textile and apparel. The department also recognized research center approval from Anna University, Chennai. Curriculum has been designed to update the knowledge of students in current technological trends.Department library is stacked with good collection of books, International and National Journals, to provide ample opportunities for the students to explore their propensity for learning and innovation in their field of study. Department has received funding worth of Rs.6.50 Crores from National Technical Textile Mission (NTTM) of Ministry of Textile (MoT) under "Education Guidelines - Enabling of Academic Institutes in Technical Textiles (Round 1.0). Department also has received funding from various other government agencies like AICTE, DST, DRDO, SERB, CSIR, etc. The department has inked Memorandum of Understanding (MoU) with leading Universities and Industries for promoting research, Internship, training, technology transfer and consultancy activities.students undergo internships at various sectors and get placed in the leading textile and apparel industry, IT companies in India and aboard as well. Department conducted training through Central and State government skill development schemes for the under privileged. Our alumni have mentoring one student to support and guide their career and also alumni have contributed many scholarships to support the need of financially suffered and meritorious students. Through alumna matter, each alumnus has mentoring one student to support and guide their career growth. Alumni also contributed many scholarships to meritorious and financially struggling students.

B.Tech Textile Technology

Vision

To be the center of excellence in textile education, training, research and service.

Mission

- To enlighten the students about the latest technology in textile industries through innovative educational practices and multi-disciplinary approach.

- To engage with the industry as solution providers through consultancy.

The PEOs of UG Programme

-

PEO1: Production Process and Solutions to Problems: Graduates are competent in

textile production processes and be able to identify problems and suggest suitable

solutions.

-

PEO2: Modern Tools & Technology and Ethics:Graduates use latest tools and

technology for the production of textile materials and serve society in an ethical

manner.

-

PEO3: Skills, Entrepreneurship and Life Long Learning:Graduates will exhibit

skills in their career and develop entrepreneurial culture through life-long learning.

The POs of UG Programme

-

PO1: Engineering knowledge: Apply the knowledge of mathematics, science, engineering

fundamentals, and an engineering specialization to the solution of complex engineering

problems.

-

PO2: Problem analysis: Identify, formulate, review research literature, and analyze

complex engineering problems reaching substantiated conclusions using first principles

of mathematics, natural sciences, and engineering sciences.

-

PO3: Design /development of solutions: Design solutions for complex engineering problems

and design system components or processes that meet the specified needs with appropriate

consideration for the public health and safety, and the cultural, societal, and

environmental considerations.

-

PO4: Conduct investigations of complex problems: Use research-based knowledge and

research methods including design of experiments, analysis and interpretation of data,

and synthesis of the information to provide valid conclusions.

-

PO5: Modern tool usage: Create, select, and apply appropriate techniques, resources, and

modern engineering and IT tools including prediction and modelling to complex

engineering activities with an understanding of the limitations.

-

PO6: The engineer and society: Apply reasoning informed by the contextual knowledge to

assess societal, health, safety, legal and cultural issues and the consequent

responsibilities relevant to the professional engineering practice.

-

PO7: Environment and sustainability: Understand the impact of the professional

engineering solutions in societal and environmental contexts, and demonstrate the

knowledge of, and need for sustainable development.

-

PO8: Ethics: Apply ethical principles and commit to professional ethics and

responsibilities and norms of the engineering practice.

-

PO9: Individual and team work: Function effectively as an individual, and as a member or

leader in diverse teams, and in multidisciplinary settings.

-

PO10: Communication: Communicate effectively on complex engineering activities with the

engineering community and with the society at large, such as, being able to comprehend

and write effective reports and design documentation, make effective presentations, and

give and receive clear instructions.

-

PO11: Project management and finance: Demonstrate knowledge understanding of the

engineering and management principles and apply these to one’s own work, as a member and

leader in a team, to manage projects and in multidisciplinary environments.

-

PO12: Life-long learning: Recognize the need for, and have the preparation and ability

to engage in independent and life-long learning in the broadest context of technological

change.

The PSOs of UG Programme

Engineering Graduates will be able to:

-

PSO1: Application of Basic Concepts: Apply fundamental concepts in the areas of

spinning, weaving, testing, garment making and processing.

-

PSO2: Solution for Industrial Problems: Solve industrial problems in textile industries

considering environmental issues to improve quality and productivity.

-

PSO3: Moral Values: Demonstrate social and ethical responsibilities relevant to textile

industries.

M.Tech Textile Technology

Vision

To be the center of excellence in textile education, training, research and service.

Mission

- To enlighten the students about the latest technology in textile industries through innovative educational practices and multi-disciplinary approach.

- To engage with the industry as solution providers through consultancy.

The PEOs of PG Programme

-

PEO1: Manufacturing Technique and Solutions to Problems: Graduates are professionally

competent in textile manufacturing technique and be able to identify problems and

suggest suitable solutions.

-

PEO2: Scientific Research Tools & Technology: Graduates follow scientific and

technological developments, to conduct research and prepare the technical reports.

-

PEO3: Interdisciplinary Skills and Entrepreneurship: Graduates will exhibit

interdisciplinary skills that results in desired textile products in their career and

develop entrepreneurial culture.

The POs of PG Programme

-

PO1: An ability to independently carry out research /investigation and development work

to solve practical problems

-

PO2: An ability to write and present a substantial technical report/document

-

PO3: Students should be able to demonstrate a degree of mastery over the area as per the

specialization of the program. The mastery should be at a level higher than the

requirements in the appropriate bachelor program

Contact Details

From the Hod's Desk

Dr G. Karthikeyan

Professor & Head

AICTE Faculty ID: 1-461760257 | College ID: CTTTF001

LinkedIn Profile | IRINS Profile | ProfileMail-ID: [email protected]

About Faculty Dr.G.Karthikeyan, is Professor and HoD of Department of Textile Technology, K.S.Rangasamy College of Technology, Tiruchengode, Tamil nadu. He is the member of Governing Council, KSRCT. He is having 22+ years of experience in Teaching, research and industry. His research areas of interest and field of practice cover chemical processing, garment technology, IoT and apparel science. He has published 17 research articles and 20 research and review papers in International and National Conferences. Under his leadership the department received Rs.6.5 Crores from National Technical Textile Mission (NTTM), Ministry of Textiles, New Delhi and also under his mentorship one idea has been selected in MSME Idea Hackathon with a total funding of Rs.14.50 Lakhs. He is recipient of “Distinguished Professor Award” and “Best Leadership Award” for his excellence activities in academic. He is the Board of member in the Textile Board for Directorate of Technical Education, Chennai and Academic Council member, for K.S.Rangasamy College of Technology. Under his leadership the department has received NBA accreditation in 2019 and 2022 and also an approval for our research center from Anna University, Chennai. He is also good cricketer, he leads the college cricket team and won the first KPL Premier League match in 2024.

Our Intellectuals

Dr.M.B.Sampath

Professor

Weaving and Garments

Dr.N.Sukumar

Professor

Textile Technology

Dr.K.Saravanan

Professor

Natural fibres, Textile composites, Marketing and Merchandising

Mr. G.Devanand

Assistant Professor

Fibre Science, Garment Manufacturing and Export Documentation

Mr. M. Arunkumar

Assistant Professor

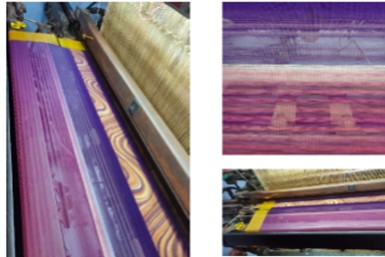

Textile Processing and Weaving

Mr. P. Maheswaran

Assistant professor

Textile Technology (Textile Chemistry)

Fibre Science, Processing & Apparel

Dr. C.Premalatha

Assistant Professor

Textile Chemical Processing, Technical Textiles

.jpg)

Mr.A.S.Subburaayasaran

Assistant Professor

Spinning and Knitting

Dr.K.R.Nandagopal

Assistant Professor

Spinning, Technical Textiles, Composites and Fibre reinforced Concrete

Mr.J. Thiyagarajan

Assistant Professor

Weaving Technology

Our Non-Teaching staffs

Students List

| S.no | Batch | Name-list |

|---|---|---|

| 1 | 2024-28 | |

| 2 | 2023-27 | |

| 3 | 2022-26 | |

| 4 | 2021-25 |

Best Outgoing Students

| S.no | Batch | Name |

|---|---|---|

| 1 | 2021-25 | Harish D |

| 2 | 2020-24 | Hema S |

| 3 | 2019-23 | Yogesh R |

Roll of Honour

| S.no | Batch | Roll of Honour |

|---|---|---|

| 1 | 2023-24 | Hema S |

| 2 | 2022-23 | Yogesh R |

| 3 | 2021-22 | Jeyakrishna N |

| 4 | 2020-21 | Jeevanantham B |

| 5 | 2019-20 | Prasanna S |

| 6 | 2018-19 | Brajesh Singh Jadoun H |

| 7 | 2017-18 | Siranjeevi S |

| 8 | 2016-17 | Infanticiya J |

| 9 | 2015-16 | Amit Srivastava S |

| 10 | 2014-15 | Priya S |

| 11 | 2013-14 | Boopathy S |

| 12 | 2012-13 | Gayathri S |

| 13 | 2011-12 | Ramya R |

| 14 | 2010-11 | Antonarputharaj J |

| 15 | 2009-10 | Senthilkumar K |

| 16 | 2008-09 | Sanjay G |

| 17 | 2008-09 | Vijayaprabhakaran S |

| 18 | 2007-08 | Krishnaramesh S |

| 19 | 2007-08 | Chinduja B |

| 20 | 2005-06 | Tharani P |

| 21 | 2004-05 | Subramani P |

| 22 | 2003-04 | Kavitha R |

| 23 | 2002-03 | Senthilkumar R |

| 24 | 2001-02 | Kalaiarasan M |

| 25 | 2000-01 | Sundaramoorthy R |

Distinguished Alumni

| S.no | Batch | Name of the Alumni | Designation |

|---|---|---|---|

| 1 | 2020-24 | Hema S | Quality Inspector |

| 2 | 2019-23 | Yogesh R | Chatbot Developer |

| 3 | 2018-22 | Jeyakrishna N | Merchandiser |

| 4 | 2017-21 | Jeevanantham B | Programmer |

| 5 | 2016-20 | Prasanna S | Section Manager |

| 6 | 2015-19 | Brajesh Singh Jadoun H | Merchandising Manager |

| 7 | 2014-18 | Siranjeevi S | Sourcing Manager |

| 8 | 2013-17 | Mr. S.Sivaprasad | R & D Engineer |

| 9 | 2010-14 | Mr. S. Mohan | Fabric Manager |

| 10 | 2010-14 | Ms. D.Hazel | Teaching Fellow in Textile Technology |

| 11 | 2009-13 | Mr. V.Vishnu | Merchandising Manager |

| 12 | 2009-13 | Mr.S.Jeyakumar | Senior Compliance Associate |

| 13 | 2008-12 | Mr. Yuvaraja.S | Senior Merchandiser |

| 14 | 2008-12 | Mr. Arun S Nair | DY Manager Purchase |

| 15 | 2008-12 | Mr. G.Karthikeyan | Operation Manager |

| 16 | 2008-12 | Mr. M.Gokul | Asst. Manager-Planning |

| 17 | 2007-11 | Mr. N.Vigneswaran | Ware House Incharge |

| 18 | 2007-11 | Mr.A. Anton Airuputharaj | Business Executive |

| 19 | 2002-06 | Dr.P.Ganesan | Assistant Professor |

| 20 | 2002-06 | Mr. I Suresh Balu | Deputy General Manager |

| 21 | 2000-04 | Dr.Subramani Pichandi | Post-Doc Researcher |

| 22 | 1999-03 | Mr. R.Sembulingam | International Consultant |

| 23 | 1999-03 | Mr.G.T.V.Prabu | Scientist |

| 24 | 1998-03 | Dr.R.Surjit | Assistant Professor |

| 25 | 1998-02 | Mr. S. Durairaj | Assistant Registrar |

| 26 | 2005-09 | Mr. A.Thambidurai | Assistant Professor |

| 27 | 2002-05 | Mr. G.Thiyagarajan | General Manager (Operations) |

| 28 | 1997-01 | Dr. R. Guruprasad | Senior Research Scientist |

| 29 | 1997-01 | Mr. S. Senthilkumar | Factory Manager |

| 30 | 1997-01 | Mr. S. Sivarajan | IT Consultant |

| 31 | 1997-01 | Mr. G. Jayabal | Factory Manager |

| 32 | 1997-01 | Mr. J. Ramesh | Senior Merchandiser |

| 33 | 1997-01 | Mr. M.R. Karthikeyan | Assistant Professor |

| 34 | 1997-01 | Mr. S. Chinnadurai | Assistant Professor |

| 35 | 1997-01 | Mr.K. Thiyagarajan | Manager - Total Quality Assurance |

| 36 | 1997-01 | Mr. P. Senthil Kumaran | Manager, Embroidery Dept |

| 37 | 1997-01 | Mr. S. Viswanathan | Divisional Merchandising Manager |

In-House Meets

Curriculum & Syllabi

Under Graduate - B.Tech(Textile Technology)

Regulation R 2022

| Batch | Syllabi |

|---|---|

| 2024-28 | |

| 2023-27 | |

| 2022-26 |

Regulation R 2018

| Batch | Syllabi |

|---|---|

| 2021-25 | |

| 2020-24 | |

| 2019-23 | |

| 2018-22 |

Regulation R 2014

| Batch | Syllabi |

|---|---|

| 2017-21 | |

| 2016-20 | |

| 2015-19 | |

| 2014-18 |

Post Graduate - M.Tech(Textile Technology)

Regulation R 2022

| Batch | Syllabi |

|---|---|

| 2024-26 | |

| 2023-25 | |

| 2022-24 |

Teaching & Learning

Video Lectures

Garments

Industrial Engineering & SCM

Merchandising & Home Textiles

Yarn Manufacturing

Product Development

| S.No. | Name Of Course | Industry Associated |

|---|---|---|

| 1. | Apparel Production Planning and Control | SA Knit wears, Madurai |

| 2. | Industrial Engineering in Textile and Clothing Industry | Remmy Tex, Tirupur |

| 3. | Digital Printing | Indigo Fusions, Bhavani |

| 4. | Garment Merchandising | SA Knit wears, Madurai |

| 5. | Denim and Washing Technology | Indigo Fusions, Bhavani |

| 6. | Garment Manufacturing Technology | GHCL,Madurai |

| 7. | Yarn Manufacturing Technology | Pallava Textiles,Thiruchengode |

E-Content

- Apparel Marketing and Merchandaising

- Financial Management and Costing for Textile and Apparel Industry

- Garment Manufacturing Technology - II

- Knitting Technology

- Protective Textile

- Structure and Properties of Fibers

- Textile and Apparel Quality Evaluation

- Technical Textiles

- Woven Fabric Structure

- Yarn Manufacturing Technology - I

| S.No. | Academic Year | No.of Students |

|---|---|---|

| 1. | 2024-25 | 60 |

| 2. | 2023-24 | 126 |

| 3. | 2022-23 | 118 |

| 4. | 2021-22 | 94 |

| S.No. | Batch | No.of Students Placed | Percentage(%) | Highest CTC |

|---|---|---|---|---|

| 1. | 2024-25 | 57 🧷 | 90% | 6 LPA |

| 2. | 2023-24 | 58 🧷 | 90% | 5.7 LPA |

| 3. | 2022-23 | 57 🧷 | 87% | 5.4 LPA |

| 4. | 2021-22 | 44 🧷 | 88% | 11.3 LPA |

| 5. | 2020-21 | 48 🧷 | 86% | 2.4 LPA |

Prime Recruiters list

| S.No. | Batch | No. of Students | Key Institutions |

|---|---|---|---|

| 1. | 2023 - 24 | 06 | NIFT, New Delhi |

| 2. | 2022 - 23 | 04 | University of East London, Docklands Campus, London

University of Hertfordshire, United Kingdom Anna University,Chennai, University of Roehampton, London |

| 3. | 2021 - 22 | 03 | SRM College of Management ,Trichirappalli |

| S.No. | Start-up Name | Title | Sanction Number |

|---|---|---|---|

| 1. | MSME champions Scheme 2022-23 | Design and Fabrication of NanoJacqard for weaving machine | F.No. 6(19)/sanction to CAN/Incubation / 2022-23 |

| S.No. | Acedamic Year | No. of Students | Examination Attended |

|---|---|---|---|

| 1. | 2023-24 | 06 | GATE-06,NIFTEE 2024 |

| 2. | 2022-23 | 01 | CEETA 2023 |

| 3. | 2021-22 | 02 | GATE-02 |

| 4. | 2020-21 | 04 | TANCET-02,GATE-02 |

Academic Laboratory

Special Laboratory

Industry supported laboratory

Type of Support: Fabrics Supply

Type of Support:Software Provider

Type of Support: Supply of Dyes,Fabrics and Chemicals

Seminar/Conference Hall

Class Rooms

No of classes : 04

Department Library

| S.No. | Particulars | Number |

|---|---|---|

| 1. | Ph.D. Doctorates | 07 |

| 2. | Ph.D. Supervisors | 03 |

| 3. | Ph.D. Pursuing | 09 |

| 4. | Ph.D. Completed | 08 |

| S.No. | Name of the Funding Agency | Title of the Proposal/Project | Investigator(s) | Amount Sanctioned (Rs.) | Status |

|---|---|---|---|---|---|

| 1 | Mag Solvics, Coimbatore | Development of Equipment for Objective Evaluation of Fabric Handle and Comfort | Dr. Bharani Murugesan, Dr. G. Karthikeyan, Dr. K. Saravanan | 9,25,000 | Ongoing |

| 2 | Arunai Creations, Gobichettipalayam | Implementation of Quality Inspection System in Garment Manufacturing Unit | Dr. N. Sukumar, Dr. K. R. Nandhagopal, Mr. M. ArunKumar | 4,10,000 | Ongoing |

| 3 | MSME, New Delhi | Digital Shuttle Box for Power Loom Controlled by Mobile App | Dr. N. Sukumar, Mr. Suguneswaran, Mr. Manikandan | 14,50,000 | Ongoing |

| 4 | MSME, New Delhi | IoT Based Humidification Plant for Small Scale Industry | Dr. N. Sukumar, Ms. Ashmita | 14,75,000 | Ongoing |

| 5 | NTTM, New Delhi | Enabling of Academic Institutes in Technical Textiles Education | Dr. R. Gopalakrishnan, Dr. G. Karthikeyan | 6,50,00,000 | Ongoing |

| 6 | Sri Shanthi Tex, Gugai Salem | Optimization in Manufacturing of Sustainable and Functional Textiles for Fashion Retail | Dr. Bharani Murugesan | 2,00,000 | Completed |

| 7 | Navasakthi Paper Boards, Erode | Development of Textile-Reinforced Paperboards for Enhanced Durability and Flexibility | Dr. K. Saravanan | 1,00,000 | Completed |

| 8 | MSME, New Delhi | Design and Fabrication of Nano Jacquard for Weaving | Dr. G. Karthikeyan | 14,50,000 | Completed |

| 09 | TNSCST, Chennai | EMF Resistant Clothing | Mrs. D. Padmalatha | 7,500 | Completed |

| 10 | TNSCST, Chennai | Non-toxic Bamboo gauze Sanitary Napkin | Mr. T. Karthikeyan | 7,500 | Completed |

| 11 | TNSCST, Chennai | Design and Development of IoT (Mobile Application) for Controlling Shuttle Box in Drop Box Power Loom | Mr. M. Arunkumar | 7,500 | Completed |

| 12 | Santi Tex, Salem | Optimization of Energy Consumption in Power Looms for Sustainable Weaving | Mrs. C. Premalatha | 1,86,000 | Completed |

| 13 | Navasakthi Paper Boards, Erode | Optimization of Felt Cloth for Enhanced Filtration Efficiency in Paper Particle Separation | Mr. P. Maheswaran | 2,50,000 | Completed |

| S.No. | Year | Book Chapters | Journals | Conference |

|---|---|---|---|---|

| 1. | 2022-25 | 05 | 48 | 51 |

Conference

| S.No. | Authors | Title of the Paper | Name of the Conference / Date | National / International |

|---|---|---|---|---|

| 1 | K.R.Nandagopal, M. Arunkumar, P. Maheswaran, B.Thirunavukarasu | Design of High Performance Electro Spun Membranes for Protective Clothing Application | International Conference on Engineering and Technology, Zigma Medicare India (OPC) Pvt Ltd., In Assoication with International Journel of Bio Sciences and Engineering, 26-27 Nov 2024. | International |

| 2 | K.R.Nandagopal | Key Note Speaker Present Trends in Engineering and Technology | International Conference on Engineering and Technology, Zigma Medicare India (OPC) Pvt Ltd., In Assoication with International Journel of Bio Sciences and Engineering, 26-27 Nov 2024. | International |

| 3 | K.R.Nandagopal, S. Arun | Development of Sustainable Printing Thickner from Tamarind Power | National Conference Cutting Edge Fashion: Blending Innovation, Functionality Sustainability and AI Integration (17-18 October 2024) | National |

| 4 | K.R.Nandagopal | Redefining Eco-Friendly Materials and Sustainable Fashion | National Conference Cutting Edge Fashion: Blending Innovation, Functionality Sustainability and AI Integration (17,18.10.2024) | National |

| 5 | Bharani Murugesan, Sajid Ahemmed Qureshi Yeshi Tadesse, Seyoum Bihonegn | Exploring the impact of jute fabric reinforcement on the mechanical characteristics of poly lactic acid composites: a research study | 7th International Conference on Technical Textiles & Nonwovens (ICTN 2023), New Delhi, During December 12-14,2023 | International |

| 6 | Sukumar Nachiappan, Moges Asmelash, G. Karthikeyan, H. Kalaiarasi, G. Poongodi | Development And Characterization of Enset Fiber Interchange Double Cloth Reinforced with Unsaturated Polyester Resin Composite | International Conference on Indo-Japan Textile Research Conference, Indian Institute of Technology Delhi and Shinshu University Japan. November 27th –28th, 2023 | International |

| 7 | Sukumar Nachiappan, G. Karthikeyan | Bamboo/Cotton Gauze Based wound dressing coated with Aloevera Rind Nanoparticle | Mahsa International Technology and Engineering Conference (Mi-Tec) 2024, Mahsa University, Malaysia 24 February 2024 | International |

| 8 | K. Saravanan, G. Karthikeyan | Study on the acoustic properties of Chicken feather fibre(CFF) and Jute Fibre(JF) composite | 3rd International Conference on Emerging Trends in Traditional and Technical Textiles, Jalandhar, NIT Jalandhar, Punjab, 28-30 April 2023. | International |

| 9 | N. Sukumar, G. Karthikeyan, V. Rabin Yusabias, M. Mangai | Protein Fiber Based Hydrogel in Combination with Chitosan and Dextrin for Chronic Wound Application | 3rd International Conference on Emerging Trends in Traditional and Technical Textiles, Jalandhar, NIT Jalandhar, Punjab, 28-30 April 2023. | International |

| 10 | N. Sukumar | Design and development of innovative fabric for air purification | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 11 | N. Sukumar | Design and development of Mobi knit app for fabric fault identifier during machine production | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 12 | G. Karthikeyan, J.Thiyagarajan | Design and manufacturing of helmet by using hybrid composite material | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 13 | G. Karthikeyan | Design and development of woven fabric for stab resistance | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 14 | G. Karthikeyan | Design and fabrication of nano jacquard | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 15 | G. Devanand | Development of Magnetic Shuttle in Handloom by Magnetic Levitation Principle | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 16 | G. Devanand | Natural Fibers Used as Composite Material in Automotive Industry | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 17 | M.Arunkumar | Design and Development of IoT Mobile Application for Controlling Shuttle box in Drop box Power Loom | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 18 | M.Arun Kumar, J.Thiyagarajan | Nontoxic Bambugoss Sanitary Napkin | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 19 | M.B. Sampath | Influence of Plasma Treatment on Comfort Properties of Regenerated Bamboo Knitted Fabric | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 20 | Bharani Murugesan | Production the conductive nylon/spandex blended filament by adding various chemicals | International Conference “Sustainable Textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 21 | Bharani Murugesan | Designing and fabrication of bio – composites for automobile application | International Conference “Sustainable Textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 22 | Bharani Murugesan | Development of flame retardant knitted and woven glass core yarn fabrics | International Conference “Sustainable Textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 23 | Bharani Murugesan | Development and characteristics of ladder effect saree by using miss pick effect | International Conference “Sustainable Textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 24 | A.S.Subburaayasaran | Development of anti – microbial finish on cotton fabric by using black turmeric | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 25 | A.S.Subburaayasaran | Development of anti – microbial finish on cotton fabric by using black turmeric | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 26 | A.S.Subburaayasaran | Analysing the manufacturing methods and finishes applied on fire retardant fabrics | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 27 | D. Padmalatha | EMF Radiation Resistant Clothing | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 28 | D. Padmalatha | Development and Characteristic of Non-Woven Fabric for Water Filtration using Chrysopogon Zizanioides | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 29 | D. Padmalatha | Development and Characterization of Baby Diaper using Hemp and its blend | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 30 | P. Maheshwaran | Treatment of Textile effluent using natural coagulant and reusage in dyeing. | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 31 | P. Maheshwaran, J.Thiyagarajan | Development and Characterisation of Medical Plasters and Bandages using Arthrospira Platensis | Sustainable Technologies and Circularity in Textile Value Chain – The Global Perspective – 2024 | International |

| 32 | P. Maheshwaran | Bio-Degradable Protective Face Mask Using Borassus Flabellifer And Gossypium Hirsutum | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 33 | P. Maheshwaran | Development and characterization of thermal protective garment | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 34 | K. Saravanan | Analysing the mechanical properties of needle Punched nonwoven fabric by using selvedge Waste | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 35 | K. Saravanan | Analysing the mechanical properties of chemical bonded nonwoven fabric by using selvedge waste | International Conference “Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 36 | D. Padmalatha | EMF Radiation Resistant Clothing | International Conference "Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 37 | C. Premalatha | Assessing The Potential of Natural Fiber Geotextiles For Sustainable Soil Reinforcement | International Conference "Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 38 | C. Premalatha | Manufacturing Of Baby Diapers Using Natural Fibre As A Core Absorbent Layer | International Conference "Sustainable textiles, fashion and craft, in Bannari Amman Institute of Technology, Sathy (STFC2K23), 2023 | International |

| 39 | Dr K.R.Nandagopal | Implementation of Individual Bale Management Systemand Comprehensive Investigation for its Spinning Performance | 9 th ACRDN Meeting and International Conference, ICAR-CIRCOT,Mumbai, ISCI,Mumbai (06-08 Dec 2023 | International |

| 40 | Dr K.R.Nandagopal | To Develop Defensive Wear with Photochromic Pigments by Using Cotton/P/C Blended Fabrics | 7th International Conference on Technical Textiles and Non Wovens, Indian Institute of Technology Delhi (IITD), New Delhi (12-14 Dec 2023) | International |

| 41 | Dr K.R.Nandagopal | Investigation of Thermal Insulation and Sound Absorption Properties for Composites made for Cotton / Polyester Recycled Non-Woven and Polypropylene | 7th International Conference on Technical Textiles and Non Wovens, Indian Institute of Technology Delhi (IITD), New Delhi (12-14 Dec 2023) | International |

Journals

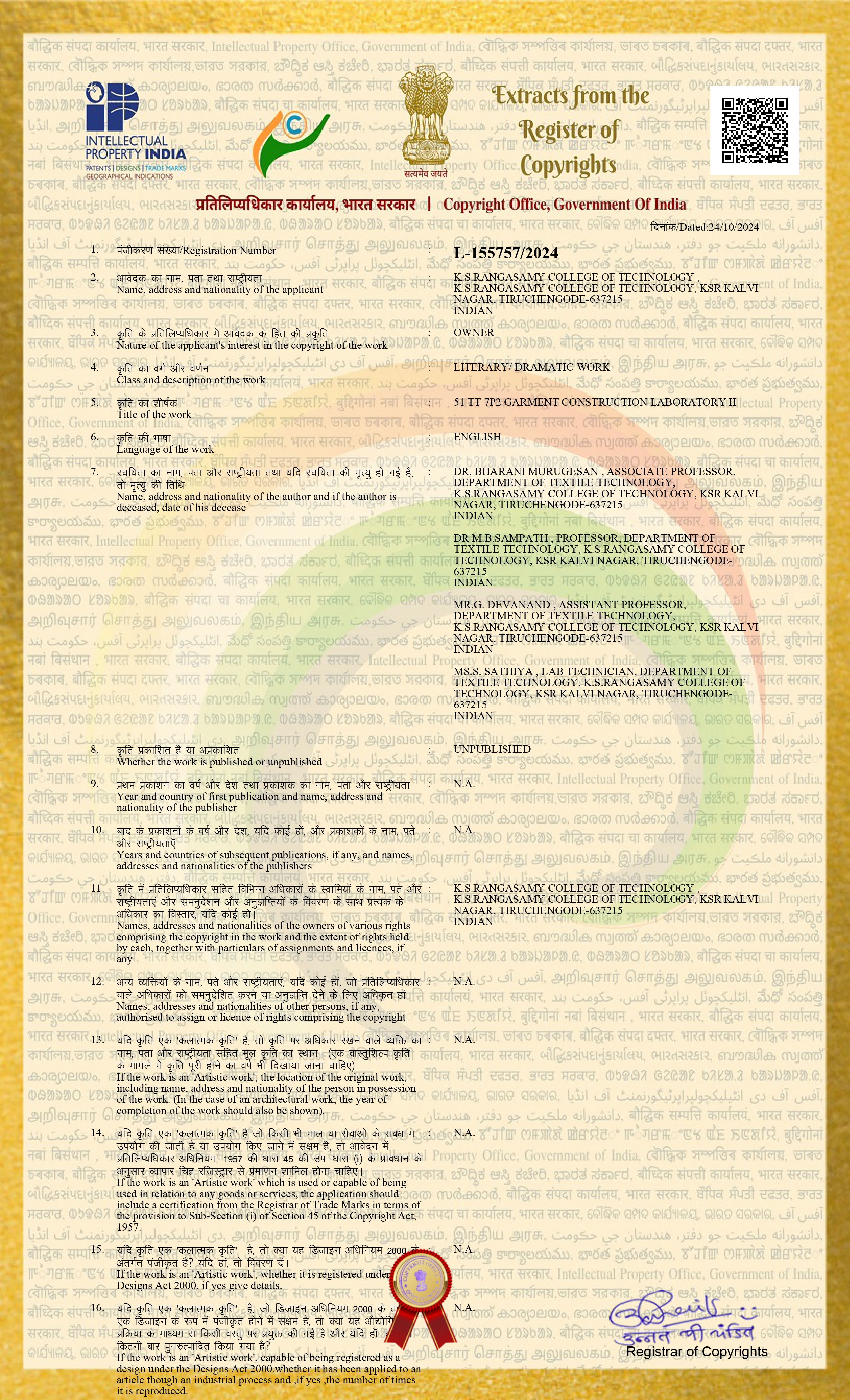

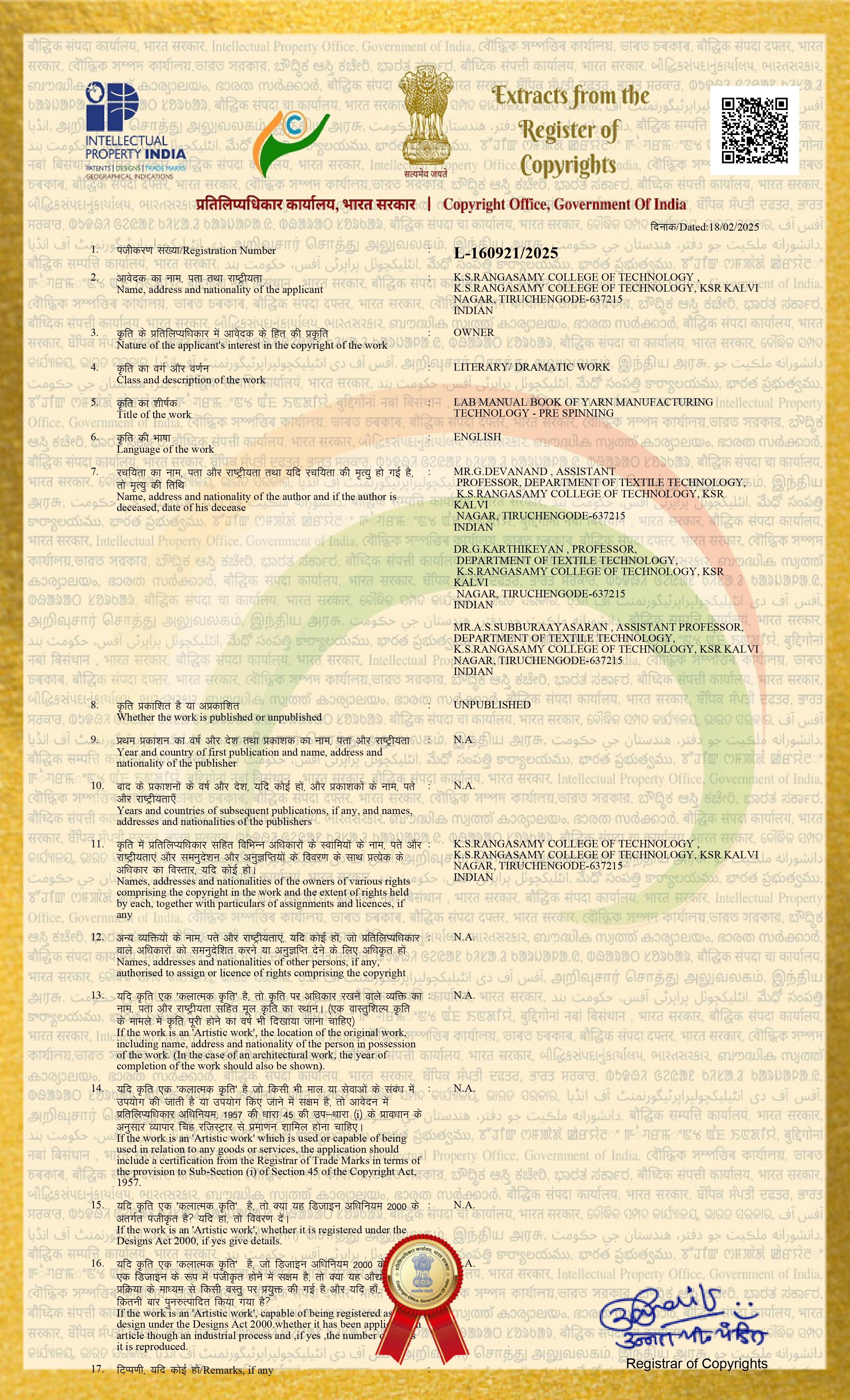

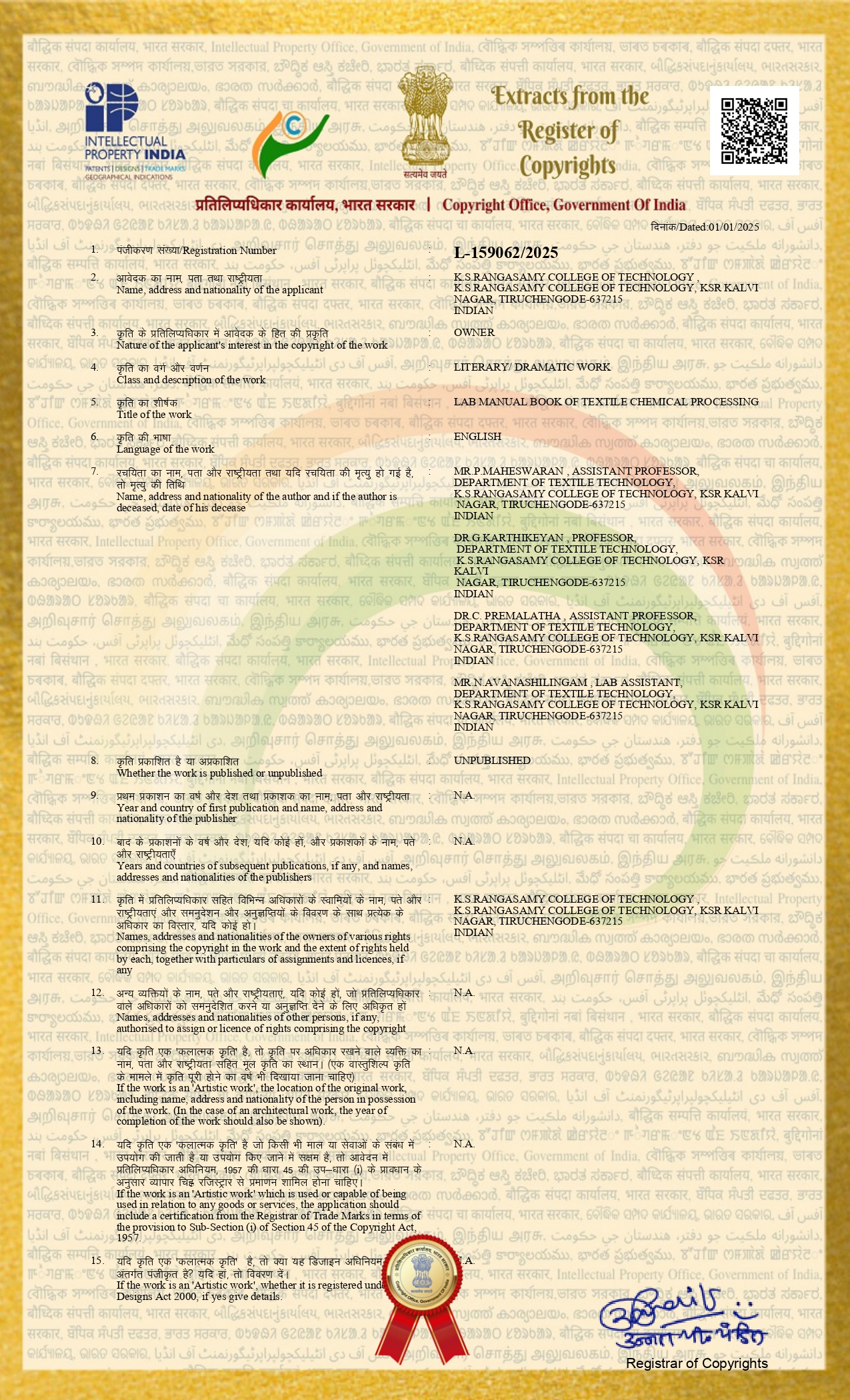

Patents/Copyrights

| S.No. | Academic Year | Name of the Patent Owner(s)/Inventor(s) | Title | Reference No. & Date | Status |

|---|---|---|---|---|---|

| 1 | 2023-24 | Dr. Bharani Murugesan, Dr. D. Srividhya, Dr. G. Karthikeyan, Dr. R. Gopalakrishnan | Textile Machines | 402185-001 | Patent / Granted |

| 2 | 2024-25 | Dr.G. Karthikeyan, Mr.K. Raguvaran, Mr.K.Poovarasan, Mr.S.Nithilan, Mr.V.Pasupathi, Mr.B. Pravin, Mr.Ragul kumar | Cost effective IoT Based Electronic Retrofit System for Mechanical Jacquard Weaving machine with Precision Control | 202441076127A, 08/10/2024 | Patent/ Published |

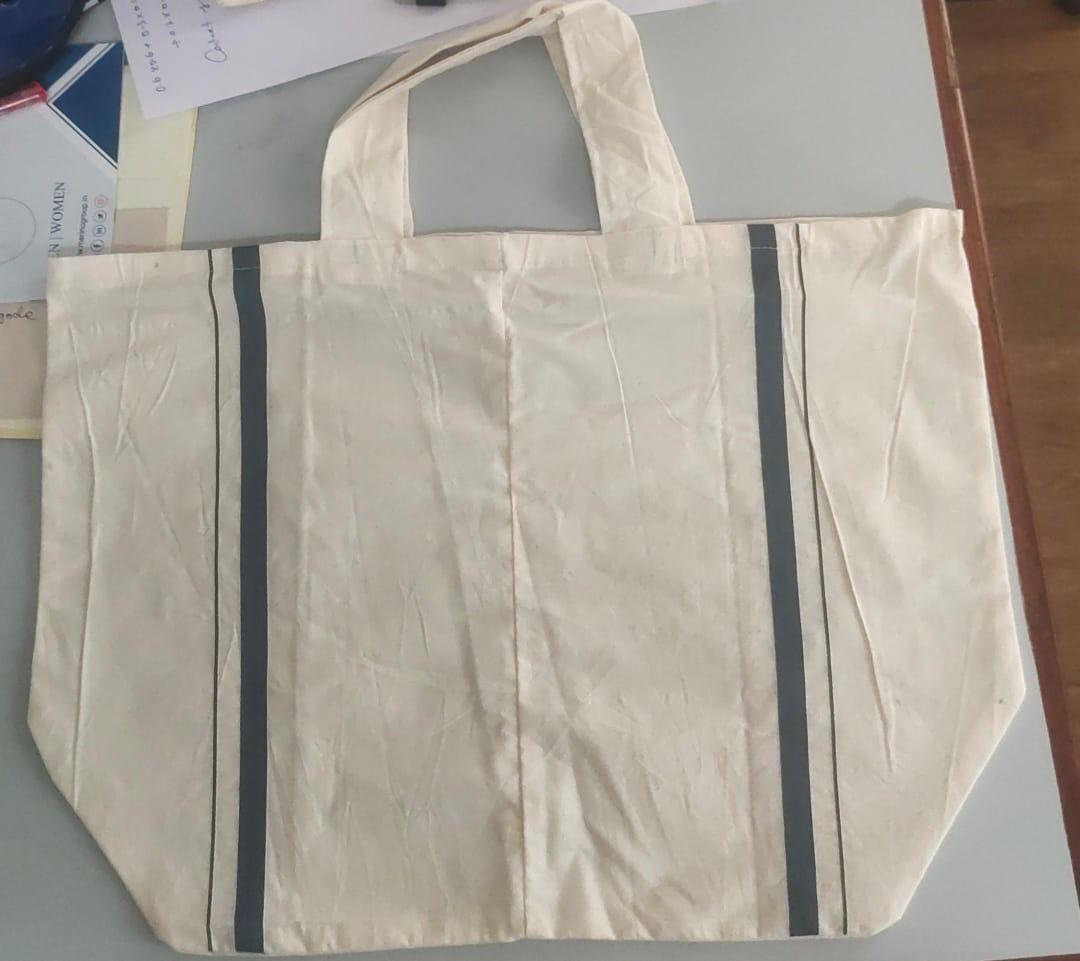

| 3 | 2024-25 | Dr.Bharani Murugesan, Mr.D.Harish, Mr.E.Saravanan, Mr.K.Anandha Kumar | Development of Bags using Weaving selvedge waste | 20244109429, 30.11.2024 | Patent/ Published |

| 4 | 2024-25 | Mr.M. Nikhil Pravin, Mr.R.K.Pavithran, Mr.K.Kiruthikraja, Dr. Bharani Murugesan, Dr.G.Karthikeyan | Development of Shape memory Lingerie for back posture rectification | 202441093988, 30.11.2024 | Patent / Published |

| 5 | 2024-25 | Mr.D.Harish, Mr.E.Saravana, Dr.Bharani Murugesan, Mr.N. Somasundaram | Integration of PNIPAM Hydrogel with IoT Sensors for Real-Time Monitoring and Enhanced wound Healing | TEMP/E-1/111335 / 2024-CHE, 05.12.2024 | Patent / Published |

| 6 | 2024-25 | Dr. Bharani Murugesan, Dr. M.B.Sampath, Mr.G. Devanand, Ms.S. Sathiya | 51 TT 7P2 Garment Construction Laboratory II | L-155757/2024 | Copyright / Granted |

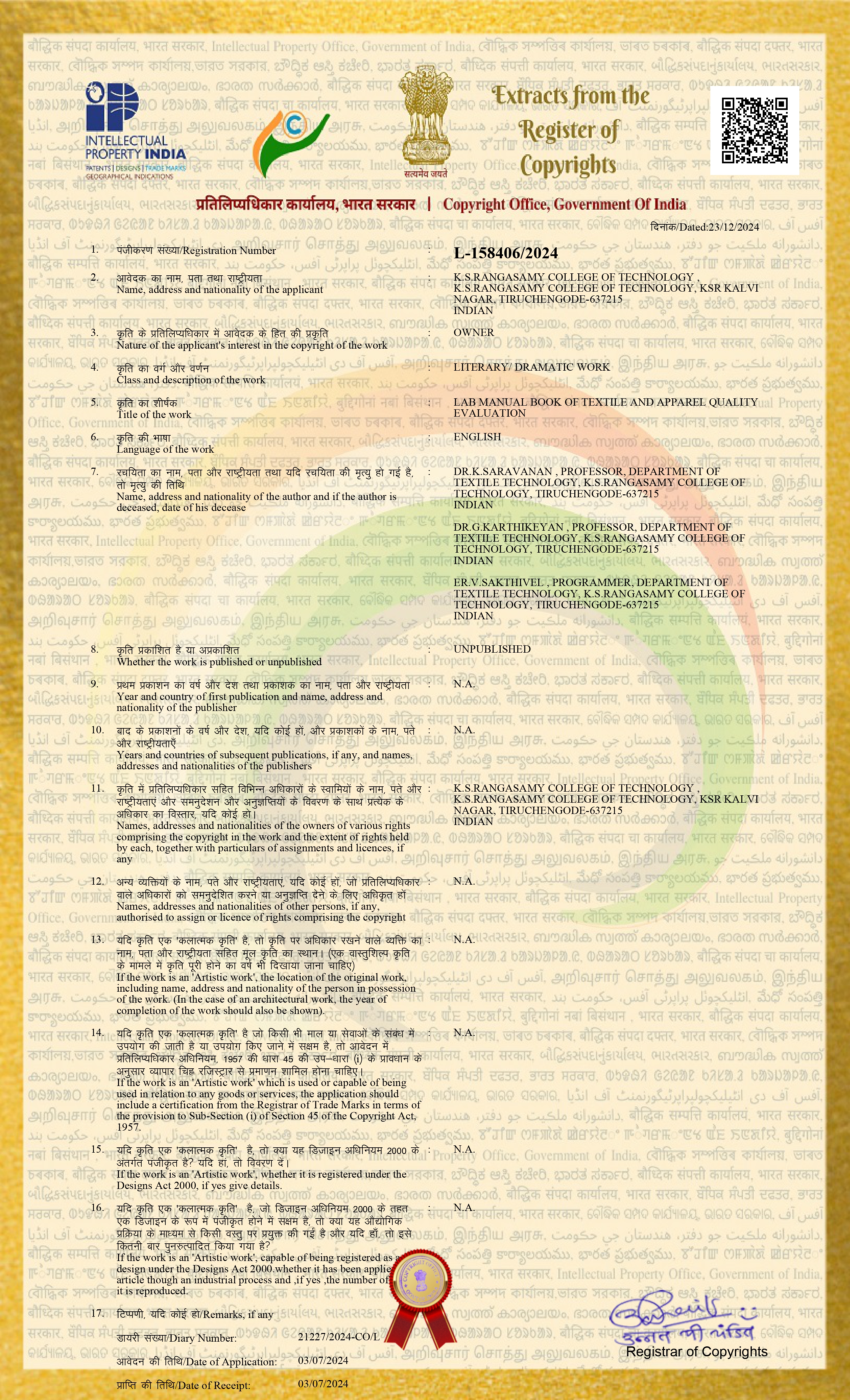

| 7 | 2024-25 | Dr. K. Saravanan, Dr. G. Karthikeyan, Mr. V. Sakthivel | Testing and Quality Evaluation Laboratory | L-158406/2024, 23/12/2024 | Copyright / Granted |

| 8 | 2024-25 | Mr. A.S.Subburayasaran, Mr. G. Devanand, Dr. G. Karthikeyan | Yarn Manufacturing Technology - Pre spinning | 32803/2024-CO/L, 18.10.2024 | Copyright / Granted |

| 9 | 2024-25 | Mr. P. Maheshwaran, Dr. G. Karthikeyan, Dr. C. Premalatha, Mr. N. Avanshilingam | Textile Chemical Processing | 31244/2024-CO/L, 07/10/2024 | Copyright / Granted |

| 10 | 2024-25 | Mr. M. Arunkumar, Dr.K.R.Nandagopal, Dr. N.Sukumar, Dr. G. Karthikeyan | Fabric Manufacturing Technology | 28380/2024-CO/L, 11/09/2024 | Copyright / Filed |

| 11 | 2024-25 | Dr.Bharani Murugesan, Mrs. V. Thulasimani, Mr.D.Harish, Mr.E.Saravanan | AI assisted Robotic arm based Pot Shaping Machine For Enhanced Craftmanship | TEMP/E-1/118530 / 2024-CHE, 05.12.2024 | Patent / Published |

| S.No. | Year | Patents/Copy Rights | ||

|---|---|---|---|---|

| Published | Granted | CopyRight Granted | ||

| 1. | 2022-25 | 04 | 01 | 06 |

Facilities

| S.NO | Academic Year | Name of faculty | Client Organization | Title of Consultancy of project | Duration | Amount received (in Rupees) |

|---|---|---|---|---|---|---|

| 1 |

2024-25 |

Dr. K. Nandhagopal | Shaharaa Tex, Karur | Enhancing Fabric Quality in Production | 1 Month | 20,000.00 |

| 2 | Dr. C. Premalatha | Sri Sivasakthi Process, Bhavani | Effluent Treatment Plant (ETP) Optimization | 1 Month | 20,000.00 | |

| 3 | Dr. N. Sukumar | S.Shanthi Tex, Salem | Predictive Maintenance System for Autolooms | 2 Months | 27,000.00 | |

| 4 | Dr. K. Saravanan | Sri Ranganayagi Textiles, Tiruchengode | Automation and Productivity Enhancement in Shuttleless Looms using Autoloom Integration | 3 Months | 40,000.00 | |

| 5 | Mr. G. Devanand | S.K.T Handlooms, Kavinthapadi | Design and Development New fabric structure using Handlooms for Handloom Products meant for Interior Decorations | 1 Month | 18,412.00 | |

| 6 | Mr. M. ArunKumar | The Galaxy, Hosur | Quality Improvement analysis of Track suits meant for Sports | 3 Months | 48,000.00 | |

| 7 | Mr. P. Maheswaran | Revive Fab, Dharmapuri | Survey study to establish Home textile Manufacturing Set UP | 3 Months | 65,000.00 | |

| 1 |

2023-24 |

Mr.A.S.Subburaayasaran | Sowmya Tex, Tiruppur | Reducing end breakage rate in dhoti production | 1 Month | 15,000 |

| 2 | Mr.P.Maheswaran | INI Krishna Tex, Tiruchengode | Enhancing fabric quality in jacquard loom production | 3 Months | 25,000 | |

| 3 | Mrs.C.Premalatha | Vinayaga Plastics, Bhavani | Reducing unevenness in mass colorization of polyvinyl chloride | 3 Months | 30,000 | |

| 4 | Dr.Bharani Murugesan | Value Fashions, Tiruppur | Implementing reduction techniques to reduce cutting waste | 3 Months | 45,764 | |

| 5 | Dr.N.Sukumar | Mani Omega Fabrics, Truchengode | Production of linen fabric in rapier loom | 3 Months | 30,000 | |

| 6 | Mr.M.Arunkumar | KandhasamyTex, Rasipuram | Increasing production efficiency in power loom | 2 Months | 25,000 | |

| 7 | Mr.G.Devanand | Care 4 You, Tiruppur | Development of biodegradable bed pad for operation theater | 3 Months | 48,000 | |

| 8 | Dr.M.B.Sampath | S. Shanthi Tex, Salem | Weft sensor problem | 2 Months | 30,000 | |

| 9 | Dr.K.Saravanan | Sujjan Tex, Tiruchengode | Reducing defects in fabric | 2 Months | 32,000 | |

| 10 | Dr.K.R.Nandhagopal | Kowsaalya Textiles, Coimbatore | Improving realization in spinning | 3 Months | 50,000 | |

| 11 | Mr.M.Arunkumar | S Brindha Garments, Namakkal | Streamlining Production Workflow for Enhanced Efficiency in Garment Manufacturing | 3 Months | 80,000 | |

| 12 | 2022-23 |

Dr.K.Saravanan | Sri Ranganayaki Textiles, Tiruchengode | Increasing machine efficiency in power loom and rapier loom | 1 Month | 20,000 |

| 13 | Mr.J.Thiyagarajan | Sowmya Tex, Kunnathur | Saree Designing using dobby pegging system | 3 Months | 40,000 | |

| 14 | Dr.Bharani Murugesan | Astrah Fashions, Tiruppur | Fabric and sewing defects in production area | 2 Months | 30,000 | |

| 15 | Dr.G.Karthikeyan | Team Spirit Sports, Bangalore | Point of Sale | 11 Months | 3,50,000 | |

| 16 | Dr.M.B.Sampath | Sree Vari Yarn Mills, Komarapalayam | Maintenance of Textile Machinery, Yarn Quality Improvement, and Manpower Training | 6 Months | 1,15,000 | |

| 17 |

2021-22 |

Mr.G.Mahaalingam | Sri Ranganayaki Textiles, Tiruchengode | Snap study on Rapier Loom | 1 Month | 20,000 |

| 18 | Mr.G.Devanand | Sujan Textiles, Tiruchengode | Modernizing of Power Looms | 1 Month | 10,000 | |

| 19 | Ms.Aishwarya V mohan | Karthick Tex, Elampillai | Dobby Design Process for Saree | 1 Month | 20,000 | |

| 20 | Mr.T.Karthikeyan | Quick Knits, Tiruppur | Needle Inventory System | 3 Months | 40,000 | |

| 21 | Mr.M.Arunkumar | Mahalakshmi Tapes, Komarapalayam | Startup marks faults on Tape loom | 2 Months | 25,000 | |

| 22 | Dr.M.B.Sampath | Sri Vishaka Tubes, Erode | Cone angle settings | 2 Months | 25,000 | |

| 23 | Mr.P.Maheshwaran | Priyanka Garments, Tiruppur | Reducing fabric waste and increase production efficiency | 2 Months | 30,000 | |

| 24 | Dr.M.B.Sampath | S worldwide, Tiruppur | Increasing throughput time in garment production department and E-Needle app | 1 Month | 20,000 | |

| 25 | Dr.N.Sukumar | Sakthi Fabrics, Salem | Production Technological adaption for weaving high-density fabrics on rapier looms | 1 Month | 20,000 | |

| 26 | Mrs.C.Premalatha | Shaharaatex, Karur | Technical Support in Home Textiles | 1 Month | 20,000 | |

| 27 | Mr.J.Thiyagarajan | Seyyon Polymers, Erode | Enhancing Mechanical Properties of Polymers through Advanced Additive Technologies | 2 Months | 41,000 | |

| 28 | Mr.M.Arunkumar | Veena Cottons, Tiruchengode | Improving Productivity and Quality in Handloom Fabric Weaving through Process Reengineering | 3 Months | 75,600 | |

| 29 | Mrs.C.Premalatha | Shanthi Processing Mills, Erode | Implementation of Sustainable Water and Energy Management in Textile Processing | 1 Month | 15,000 | |

| 30 | Mr.G.Devanand | Rodamine Apparel India (P) Ltd., Tiruppur | Integration of Sustainable Practices in Garment Production | 2 Months | 62,000 |

MOUs

| S. No. | Date of Signing | Name of the Company | Validity |

|---|---|---|---|

| ACADEMIC YEAR (2024 – 2025) | |||

| 1 | 25.04.2025 | Texcoms Textile Solutions, Coimbatore | 25.04.2028 |

| 2 | 24.01.2025 | CARE 4 U India PVT., LTD., Tirupur | 24.01.2028 |

| 3 | 24.01.2025 | True Worth Inc (Hosiery Manufacturer & Exporter), Tirupur | 24.01.2028 |

| ACADEMIC YEAR (2023 – 2024) | |||

| 4 | 28.02.2024 | S.A.Knitwears Pvt Ltd, Madurai | 28.02.2029 |

| 5 | 21.06.2023 | Best Colour Solutions India Pvt. Ltd, Perundurai | 21.06.2026 | 6 | 21.06.2023 | Gainup Group of Companies, Dindigul | 21.06.2026 |

| ACADEMIC YEAR (2022 – 2023) | |||

| 7 | 28.02.2023 | MAG Solvics Pvt. Ltd., Coimbatore | 28.02.2028 |

| 8 | 19.01.2023 | Centre of Excellence: Apparel, Made - Ups & Home Furnishing Sector Skill Council, Tirupur | 19.01.2026 |

| 9 | 05.01.2023 | Giles Brooker Group, New Zealand | 05.01.2028 |

| 10 | 26.08.2022 | IIHT, Fulia, West Bengal | 26.08.2028 |

| 11 | 26.08.2022 | Indigo Fusion, Erode | 26.08.2028 |

| ACADEMIC YEAR (2021 – 2022) | |||

| 12 | 18.03.2022 | Gemini CAD Systems, Romania | 18.03.2027 |

| 13 | 12.08.2021 | Varifabs, Erode | 12.08.2026 |

| 14 | 12.08.2021 | Sakthi Fabrics, Salem | 12.08.2026 |

| 15 | 12.08.2021 | Playfiks, Chennai | 12.08.2026 |

| 16 | 12.08.2021 | Spade Works Sourcing, Chennai | 12.08.2026 |

Centre of Excellence

| S.NO. | Centre of Excellence |

|---|---|

| 1. | Gemini CAD-Romania |

| 2. | Centre of Excellence in Technical Textiles |

| 3. | Auto Desk Fusion 360 Centre of Excellence for Modeling and Simulation |

| S.No. | Academic Year | Curricular Activities Participation | Curricular Activities Prize Won | Co-Curricular Activities | Extra-Curricular Activities |

|---|---|---|---|---|---|

| 1 | 2024-25 | 102 | 22 | 5 | 2 |

| 2 | 2023-24 | 199 | 21 | 2 | 3 |

| 3 | 2022-23 | 111 | 31 | 5 | - |

| S.No. | Academic Year | Name of the Event | Name of the Participant | Participated / Prize Won |

|---|---|---|---|---|

| 1 | 2022-23 | Chadar 2023 | Prasanth S | I Prize |

| 2 | 2022-23 | Chadar 2023 | Srinithi N | I Prize |

| 3 | 2022-23 | Texplosion & Festido'23 | Sujeet S | I Prize |

| 4 | 2022-23 | Texplosion & Festido'23 | Arjun P | II Prize |

| 5 | 2022-23 | Texplosion & Festido'23 | Bharani M | I Prize |

| 6 | 2022-23 | Texplosion & Festido'23 | Jai Chandru B | I Prize |

| 7 | 2022-23 | Texplosion & Festido'23 | Sujeet S | II Prize |

| 8 | 2022-23 | Texplosion & Festido'23 | Indhira Kumar R | I Prize |

| 9 | 2022-23 | Texplosion & Festido'23 | Harini K | I Prize |

| 10 | 2022-23 | Texplosion & Festido'23 | Veeraragavan V | II Prize |

| 11 | 2022-23 | Texplosion & Festido'23 | Vinoth Kumar S | II Prize |

| 12 | 2022-23 | Texplosion & Festido'23 | Kiruthik Raja K | III Prize |

| 13 | 2022-23 | Texplosion & Festido'23 | Thakchanamoorthi M V | III Prize |

| 14 | 2022-23 | Texplosion & Festido'23 | Indhira Kumar R | I Prize |

| 15 | 2022-23 | Texplosion & Festido'23 | Harini K | I Prize |

| 16 | 2022-23 | Texplosion & Festido'23 | Vasikaran V | II Prize |

| 17 | 2022-23 | Texplosion & Festido'23 | Kiruthik Raja K | II Prize |

| 18 | 2022-23 | Texplosion & Festido'23 | Nikhil Pravin M | II Prize |

| 19 | 2022-23 | Texplosion & Festido'23 | Suryaprasanth R | II Prize |

| 20 | 2022-23 | Fashion Fest2k23 | Ranjithkumar R | II Prize |

| 21 | 2022-23 | Fashion Fest2k23 | Harini K | II Prize |

| 22 | 2022-23 | Fashion Fest2k23 | Varunraj N | Best Performance Award |

| 23 | 2022-23 | Project Exhibition Cum Contest 2023 | Obu Umamaheswari M | I Prize |

| 24 | 2022-23 | Project Exhibition Cum Contest 2023 | Moulidharan M | I Prize |

| 25 | 2022-23 | Project Exhibition Cum Contest 2023 | Santhosh P | II Prize |

| 26 | 2022-23 | Project Exhibition Cum Contest 2023 | Suganeswaran M | III Prize |

| 27 | 2022-23 | Good Performance in the Textile Spinning Technology subjects | Yogesh R | Precitex Award |

| 28 | 2022-23 | Good Performance in the Textile Spinning Technology subjects | Guruharan R | Precitex Award |

| 29 | 2022-23 | Fifth Award Ceremony | Vasantha Kumar B | Best College Student Award |

| 30 | 2022-23 | Fashionk22 Giltz | Gokul S | III Prize |

| 31 | 2022-23 | Fashionk22 Giltz | Hari I | III Prize |

| S.No. | Academic Year | Name of the Event | Name of the Participant | Participated / Prize Won |

|---|---|---|---|---|

| 1 | 2024-25 | Student Project Scheme, Tamilnadu State Council for Science and Technology | Harish D, Saravanan E, Somasundaram V | ₹7,500 |

| 2 | 2024-25 | Silk Tech 2025 Project Presentation, Central Silk Board | Arun S.R., Ruban Raj N | ₹10,000 |

| 3 | 2024-25 | Bagathon 2024, Pollution Control Board, Tamilnadu | D.Harish, E. Saravanan | ₹1,00,000 |

| 4 | 2024-25 | ED-II Hackathon 2024, EDII, Tamilnadu | V. Gokuluvasan, V. Gopinath | ₹1,00,000 |

| 5 | 2024-25 | Start-up TN 1.0 State level Hackathon, Start Up TN 1.0, Tamilnadu | T. Harikrishnan, S. Hariprasath, G.M. Sethubharathi | ₹1,10,000 |

| 6 | 2023-24 | MSME Idea Hackathon 3.0, MSME, Government India, New Delhi | M.P. Asmitha | ₹14,75,000 |

| 7 | 2023-24 | MSME Idea Hackathon 2.0, MSME, Government India, New Delhi | K. Manikandan, M.Suganeswaran | ₹14,50,000 |

| 8 | 2022-23 | Next Generation Hand Crafts Skill Competition 2022-23, Department of Hand Crafts Skill Development, Government of Tamilnadu | S. Sathishkumar | ₹2,000 |

| 9 | 2022-23 | MSME Idea Hackathon 1.0, NSME, Government of India, New Delhi | V.Pasupathi, K. Poovarasan, S. Govindaraj | ₹14,50,000 |

| 10 | 2022-23 | Student Project Scheme, Tamilnadu State Council for Science and Technology | K. Manikandan, M.Suganeswaran | ₹7,500 |

| 11 | 2022-23 | Student Project Scheme, Tamilnadu State Council for Science and Technology | G. Bommu Saravan, S. Swathi | ₹7,500 |

| 12 | 2022-23 | Student Project Scheme, Tamilnadu State Council for Science and Technology | S. Bharathkumar, R. Sabari Sree Aravind | ₹7,500 |

| S.No. | Academic Year | Name of the Event | Name of the Participant | Participated / Prize Won |

|---|---|---|---|---|

| 1 | 2023-24 | Inner Wheel Club of Rasipuram, Silambattam Contest ‘24 | K. Shanmuga Priya | Best Performance |

| 2 | 2023-24 | Valvil Ori Silambattam Association, Rasipuram, Silambattam Contest ‘24 | K. Shanmuga Priya | I Prize |

| 3 | 2023-24 | Royal Academy of Warriors, Coimbatore, Open level State Level Silambam | K. Shanmuga Priya | I Prize |

| 4 | 2024-25 | Tamil Nadu Wushu Association, Chennai, 22nd Junior, Senior Tamilnadu State Wushu Championship 2025 | Naveenkanth K | Gold Medal (Xingyi Quan) |

| 5 | 2024-25 | All India Inter University Wushu Competition, Mohali | Naveenkanth K | Bronze Medal |

KSRCT TECHNICAL TEXTILE PARK

A Textile Park is a dedicated industrial zone aimed at

boosting the textile and apparel sector by providing state-of-the-art infrastructure,

fostering innovation, and promoting sustainable practices. These parks are designed to

integrate the entire textile value chain, from raw material processing to the production

of finished goods, under one roof.

Magazine

| Academic Year | Magazine |

|---|---|

| 2024-25 | |

| 2023-24 | |

| 2022-23 | |

| 2021-22 | |

| 2020-21 | |

| 2019-20 |

Newsletter

| Academic Year | Period | Newsletter |

|---|---|---|

| 2024-25 | June-November | |

| 2023-24 | June-November | |

| 2023-24 | Dec-May | |

| 2022-23 | June-November | |

| 2022-23 | Dec-May | |

| 2021-22 | June - November | |

| 2021-22 | Dec-May | |

| 2020-21 | June-November | |

| 2020-21 | Dec-May | |

| 2019-20 | June-November | |

| 2019-20 | Dec-May |

TAFETA Association

- Office Bearers

- Faculty President:

- Dr. G. Karthikeyan, HoD-Textile

- Faculty Coordinator:

- Dr. C. Premalatha

- President:

- Ms. Harini K

- Vice-President:

- Ms. P.R. Sowndharya

- Treasurer:

- Mr. R. Indhirakumar

- Members:

- All Students of the Textile Department

| Academic Year (2024-25) | ||||

|---|---|---|---|---|

| S.No. | Date | Name of Event | Resource Person | |

| 1 | 24.04.2025 | Workshop on TexHub365-AI in Textile | Mr. Kanthimathinathan, CEO, WINSYS SMC, Covai Mr.A.T.Kumar, CPTO, TEXCOMS Worldwide, Covai |

|

| 2 | 28.03.2025 - 29.03.2025 |

Dakshaa T 25 Workshop on Medical Textiles | Mr.Suresh Ram, Proprietor, Care4u India Pvt. LTD. | |

| 3 | 14.12.2024 | TAFETA Alumni Reunion | 2019-2023 Alumnus | |

| 4 | 23.11.2024 | Parents Meeting | All Parents and Guardians | |

| 5 | 21.11.2024 | Sewing Threads: Processing and Finishing | Ms.S.Indudevi, Lab Assistant Manager, Madura Coats, Madurai | |

| 6 | 15.11.2024 | Inauguration function of TAFETA and National Handloom Day Celebration Seminar on “Awareness on Handloom Mark, Silk Mark, Indian Handloom Brand with GI Tag” |

Mr.N.Jegadeesan, Junior Technical Assistant, Department of Handlooms, Erode Mr.N.Ponmarimuthu, Proprietor, Handloom Products Manufacturer & Senior Handloom Weavers |

|

| 7 | 05.11.2024 | Women Empowerment | Ms.N.Rajashree, Planning Manager, Atraco Groups Pvt LTD, Dubai | |

| 8 | 05.11.2024 | Guest Lecture on “The Future of Global Fashion Manufacturing: Innovations, Challenges, and Opportunities” | Ms.N.Rajashree, Planning Manager, Atraco Groups Pvt LTD, Dubai | |

| Academic Year (2023-24) | ||||

|---|---|---|---|---|

| S.No. | Date | Name of Event | Resource Person | |

| 1 | 29.05.2024 | Guest Lecture on “Quality Testing in Textile Processing” | Mr.R. SounderRaj, Internal and External Auditor, BARC-Mumbai | |

| 2 | 24.04.2024 | Guest Lecture on “Medical Textiles: A Sustainable Approach” | Dr.A.Jesica Roshima, Assistant Professor, Department of Fashion Technology, VIT Fashion Institute of Technology, Chennai | |

| 3 | 06.03.2024 | Designer Club Inauguration and webinar on Recent Trends on Fashion | Mrs.Archana Prasad, Designer, Archanaas Aakriti, Founder and Designer, Coimbatore | |

| 4 | 02.03.2024 | Workshop on Style Symphony-Crafting Choreography with Counter Charm | Mrs.G.Dhanapriya, Assistant Professor, Department of TT, KSRCT | |

| 5 | 30.01.2024 | World Skills Initiative: Empowering Textile Students for Excellence | Mr.A.Naveen Sankar, India Skill Consultant, Chennai | |

| 6 | 15.11.2023 | Inauguration function of TAFETA | S.Arunagiri, Managing Director, Vedha Fabrics, Bhavani | |

| Academic Year (2022-23) | ||||

|---|---|---|---|---|

| S.No. | Date | Name of Event | Resource Person | |

| 1 | 21-06-2023 | Valedictory and MoU Signing Ceremony |

Mr.R.Karthikeyan, General Manager, Best Colour Solutions, Chittode, Tirupur Mr.C.Gangadharan, Gain Up Group of Companies, Thindugal |

|

| 2 | 24-04-2023 | Dakshaa T23 | Mr.Suresh Ram, Proprietor, Care4u India Pvt. LTD. | |

| 3 | 17-04-2023 | Webinar on Medical Textiles | Mr.Suresh Ram, Proprietor, Care4u India Pvt. LTD. | |

| 4 | 13-03-2023 | Magik 2k-23 | Mr.Giles Brooker, Giles Brooker Group, New Zealand | |

| 5 | 08-03-2023 | Women Empowerment | Mrs.Deepasri, Designer, Associate Dean, Vogue Institute of Arts and Design, Bangalore | |

| 6 | 13-02-2023 | Workshop on Weaving Techniques and Calculations |

Mr.A.Subramani, Proprietor, Sri Kandhaguru Tex Mr.K.Ravi, MD, Saranya Tex.T.Code |

|

| 7 | 02-02-2023 | Webinar on Colour Reproduction for Textile Printing | Dr.A.Arulmozli, Associate Professor, Department of Printing Technology, Avinashilingam Institute of Home Science and Higher Education, Coimbatore | |

| 8 | 18-11-2022 | Inauguration of TAFETA Association for 2022-2023 | Mr.J.Parameshwaran, Assistant Director, Textile Committee, Tirupur | |

| 9 | 07-10-2022 | Kasturi Cotton Quiz | Dr.A.Arputharaj, Senior Scientist (Textile Chemistry), CIRCOT, Mumbai | |

Professional Body

The Textile Association of India

- Name of the professional Body: The Textile Association of India

- Office Bearers

- President:

- Ms. Hiroshini S G

- Vice-President:

- Ms. Subhalakshmi B

- Mr. Ajay Sakthi R

- Secretary:

- Ms. Rajalakshmi K

- Joint Secretary:

- Ms. Shanmughapriya K

- Ms. Varshini K

- Treasurer:

- Mr. Arun S R

- Mr. Hiruthik R

| Academic Year (2024-25) | ||||

|---|---|---|---|---|

| S.No. | Date | Name of Event | Resource Person | |

| 1 | 28.11.2024 | Application of Numerical Methods in Textile Automated Inventory Management in Apparel Production: Reducing Overstock and Shortages | Dr. S. Sudha, Assistant Professor (SG), Hindustan Institute of Technology and Science, Chennai | |

| 2 | 26.10.2024 | Pioneering the Future of Smart Textile Materials with Innovations | Dr. D. Vasanth Kumar, Assistant Professor (SR) & HoD, VIT Fashion Institute of Technology (VFIT), VIT, Chennai | |

| 3 | 18.10.2024 | Innovation in Merchandising and Product Development | Mr. M. Arun Krishna Deva, Sr. Merchandiser, M/s. White House Export Ltd., Chennai | |

| 4 | 23.09.2024 | Innovation and New Trends in Textile Fabric Structure | Mr. Anas Shah B, Senior Lecturer (Textiles), Indian Institute of Handloom Technology, Fulia, Nadia, West Bengal | |

| 5 | 21.09.2024 | Empowering Minds Shaping Futures: Entrepreneurial Pathway and MSME Initiatives for Success | Mr. G. Vasudevan, Coordinator Entrepreneurship Development and Innovation Institute, District Co-Ordinator, Collectorate, Namakkal | |

| 6 | 27.08.2024 | Kickstart Your Textile Entrepreneurship Journey | Mr. Lalith Sanjeevi, Textile Business Consultant, Researcher, and Fashion Enthusiast, Chennai | |

| 7 | 24.08.2024 | Equip Yourself for Employment in Industry | Mr. T. Dinesh Kumar, Asst. Manager - HR, Rieter India Pvt Ltd, Coimbatore | |

| 8 | 23.08.2024 | Emerging Innovations in E-Textiles and Their Role in Shaping the Future of Smart Fabrics | Dr. P. Jagajanantha, Senior Scientist at ICAR-CIRCOT, Mumbai | |

| 9 | 29.07.2024 | Innovations in Digital Marketing and Fashion Branding | Ms. Shree Lekha, Head Marketing, Maybel, Chennai | |

| 10 | 19.07.2024 | Cyber Innovation Enhancing Awareness for Securing Your Digital Life | Dr. M. Senthil Kumar, (International Certified Cyber Security Analyst), Professor & Head, Department of Cyber Security, SRM Valliammai Eng College, Chennai | |

| 11 | 28.06.2024 | Innovative Approaches to Tap the Career Opportunities in the Textile Testing Sector | Mr. A. Saleemraja, Assistant Manager of Quality Assurance at TUV SUD South Asia Pvt Ltd, Ranipet, Chennai | |

| 12 | 20.06.2024 | Innovative Techniques Adopted in Sourcing Home Textile Materials | Mr. D. Satheeshkumar, Entrepreneur & Former DGM Arvind Life Style Brands Ltd., Bengaluru | |

| Academic Year (2023-24) | ||||

|---|---|---|---|---|

| S.No. | Date | Name of Event | Resource Person | |

| 1 | 03.04.2024 | Innovations in Knitwear Production | Dr. T. Saravanakumar, Founder & Director at Dev Innotech LLP, Karur | |

| 2 | 06.03.2024 | Recent Trends on Fashion | Ms. Archana Prasad, Designer, Archanaas Aakriti, Founder and Designer, Coimbatore | |

| 3 | 24.02.2024 | Opportunities And Challenges In Exports Of Textiles | Mr. R. Chandran, Deputy Director, Export Promotion & Quality Assurance Division, Textiles Committee, Ministry of Textiles, Government of India, Mumbai | |

| 4 | 05.01.2024 | Innovative Techniques used in Wet Processing Industry | Mr. J. Karthikeyan, General Manager, Ideal Textile Processers, Komarapalayam | |

| 5 | 19.12.2023 | Biopolymers Of Wound Dressing Applications | Dr. P. Ganesan, Assistant Professor (SG), PSG College of Technology, Coimbatore | |

| 6 | 27.11.2023 | Industry Requirement Of Quality Assurance & Control | Mr. R. Muruganandan, Senior Trainer, SGS Testing Industries Pvt Ltd, Tirupur | |

| 7 | 15.11.2023 | Wantrepreneur to Entrepreneur - Need of the Hour | Mr. S. Arunagiri, Vedha Fabrics, Bhavani | |

| 8 | 27.10.2023 | “Problems to Progress" Innovations in the Spinning Industry | Mr. P. Karnan, Regional Sales Manager, Coimbatore | |

| 9 | 23.09.2023 | Innovation & Entrepreneurship in Garment Manufacturing (Industry 4.0) | Mr. S. Boopathy, Operation Excellence, Page Industries Limited, Mysore | |

| 10 | 11.09.2023 | Innovative Business Models for Textile Retailing | Mr. Kaarthikeyan Gopal, Senior Manager, Business Development Arvind Limited, Ahmedabad | |

| 11 | 05.09.2023 | The Handloom Reservation Act-1985 | Mr. KA.RA.Jayavel Ganesan, Assistant Enforcement Officer, Tiruchengode | |

| 12 | 30.08.2023 | Supply Chain Management In Textile Industry | M. Yokesh, Merchandiser, Eastman Exports Pvr Ltd, Perundurai, Erode | |

| 13 | 26.08.2023 | Entrepreneurship Opportunities in Textile Sector | Mr. G. Devanand, Assistant Professor, K.S. Rangasamy College of Technology, Tiruchengode | |

| 14 | 27.07.2023 | Skill To Empower As A Qualified Textile Professional And Entrepreneur | Mr. V. Vimalraj, Managing Director, Varnamayaa Dyechem Pvt Ltd & Elevar Fashion, Tirupur | |

| 15 | 24.07.2023 | Industrial Engineering In Textile Industry | Mr. R. Sembulingam, Senior Merchandiser, Victos Industries PVT Limited, Tirupur | |

| 16 | 19.07.2023 | Readiness Towards Tomorrow – An Entrepreneur View | Mr. A. Imran Khan, HR Site Head – Tirupur & Chennai | |

| 17 | 17.06.2023 | Innovative Practices in Shuttleless Weaving | Dr. Sajid Ahmed Qureshi, Assistant Professor, Department of Textile Engineering, Wollo University, Kombolcha, Ethiopia | |

| Academic Year (2022-23) | ||||

|---|---|---|---|---|

| S.No. | Date | Name of Event | Resource Person | |

| 1 | 26.04.2023 | Startup Business and Loan Opportunity in Textile Industry | Mrs. G. Kavitha, Branch Manager, Indian Bank, Bhavani | |

| 2 | 17.02.2023 | Employable Skills for Success in Textile Industry | Mr. K. Kannan, Director-Universal Group, Hon. Secretary- The Textile Association (India), Karnataka Unit, Bengaluru | |

| 3 | 16.12.2022 | Entrepreneurship Development Programme | Dr. Mai Gnanam, Assistant professor & Head, Department of BBA, Arulmigu Arthanareeswarar Arts and Science College, Tiruchengode | |

| 4 | 16.12.2022 | Entrepreneurship Development Programme | Dr. Ramanigopal, Treasurer, Salem District Small Scale – Tiny Industries Associations, Salem | |

| 5 | 24.11.2022 | Smart Production Strategies in Apparel Manufacturing | Mr. K. Kannan, Director-Universal Group, Hon. Secretary- The Textile Association (India), Karnataka Unit, Bengaluru | |

| 6 | 03.11.2022 | Streamlining Spinning Processes with Technology | G. Kaarthikeyan, Raymond Limited, Business Development Manager, South India | |

| 7 | 20.10.2022 | Salesmanship Skills in the Apparel Industry | S. Arun Prasad, Managing Director, Aiswariyaa Packaging, Tirupur | |

| 8 | 18.10.2022 | Finance for Apparel Startups: Tips and Strategies | S. Suresh, Block Dobby Clothing Pvt. Ltd., Bengaluru | |

| 9 | 03.10.2022 | Labor-Saving Techniques in Textile Operations | G. Thiyagarajan, General Manager, Operations, Jupiter Knitting Mills, Tirupur | |

| 10 | 22.09.2022 | PR Awareness Programme under National Intellectual Property Awareness Mission | Mr. M. Madhanraj, Examiner of Patent Trainer, Indian Patent Office | |

| 11 | 21.09.2022 | Sustainable Practices in Textile Design and Production | S. Arun Prasad, Managing Director, Aiswariyaa Packaging, Tirupur | |

| 12 | 08.08.2022 | Entrepreneurship in Medical Textile | Mr. Suresh Ram T, Proprietor, Care 4 U Pvt Ltd, Tirupur | |

The Institution of Engineers(India)

- Name of the profession Body:The Institution of Engineers(India)

| Academic Year (2024-25) | ||||

|---|---|---|---|---|

| S.No. | Date | Name of Event | Resource Person | Organization |

| 1 | 24.12.2024 | Sustainable Garment Production with Automation: Energy, Labor, and Resource Efficiency | Mohammed Feroze M | Sourcing and Quality Assurance Manager, Claire Group A/S, Denmark, Tirupur |

| 2 | 23.12.2024 | Lean Manufacturing in Weaving Industry: Combining Automation with Process Optimization | Maheswari V | Proprietor, Sabari Tex, Namakkal |

| 3 | 23.12.2024 | Workforce Empowerment Through Automation: Redefining Labor Roles in Denim Fabrics Production | Balachander M | Factory Manager, K.G Denim Pvt Ltd, Mettupalayam |

| 4 | 18.12.2024 | The Role of Merchandiser in Garment Design and Production | Maryrosaly C | Merchandiser, RTR Garments, Tirupur |

| 5 | 08.12.2024 | 3D Pattern Making and Virtual Fitting: Saving Time and Improving Fit | Manoranjith S | Manager, Bhavanya Tex, Tirupur |

| 6 | 25.09.2024 | AI-Powered Quality Inspection Systems for Apparel Manufacturing | Kathiravan K.R | Merchandiser, Prachi Exports, Tirupur |

| 7 | 25.09.2024 | Digital Cutting and Stitching: Enhancing Precision and Reducing Wastage | Vimalraj C | Merchandiser, TSK Garments, Tirupur |

| 8 | 24.09.2024 | IoT in Garment Manufacturing: Real-Time Monitoring and Quality Control | Gopinath S | Buying QC, March Work Pvt Ltd., Tirupur |

| 9 | 19.09.2024 | Smart Factories: Revolutionizing Apparel Manufacturing with Automation | Chakkaravartee M | Managing Director, Ajna Clothing, Tirupur |

| Academic Year (2023-24) | ||||

|---|---|---|---|---|

| S.No. | Date | Name of Event | Resource Person | Organization |

| 1 | 10.05.2024 | Innovations in Nonwoven Structures | Dr. J C Sakthivel | Associate Professor, Department of Textile Technology, PSG College of Technology, Coimbatore |

| 2 | 18.04.2024 | Innovation in Medical Textiles and Testing Methods | Ms. M. Jercy | Manufacturing Executive, Madura Coats Pvt. Ltd., Kanyakumari |

| 3 | 27.03.2024 | Innovation in Medical and Defence Textiles | Mr. T. Sureshram | Proprietor, Care 4 U Pvt Ltd, Tirupur |

| 4 | 23.03.2024 | Innovative Practice in Textile Testing | Mr. P. Bala Saravanan | Assistant Manager, Intertek India, Tirupur |

| 5 | 15.03.2024 | Startup Opportunities in Supply Chain Management for Textile Material Exports | Mr. M. Nagarajan | Partner, GLV Logisticx, Coimbatore |

| 6 | 22.02.2024 | Innovative Braiding in the Startup Landscape of the Textile Industry | Dr. Zunjarrao Bapuso Kamble | Assistant Professor, Department of Textile Technology, National Institute of Technology, Jalandhar |

| 7 | 10.02.2024 | Unlocking Entrepreneurial Opportunities for Early-Stage Innovators in the Textile Industry | A. Gnanasambandham | Group Project Manager, HCL Technologies Ltd., Chennai & Proprietor: Ancient King of Garments, Tiruchengode |

| 8 | 19.01.2024 | Innovative and Entrepreneurial Opportunities in Textile and Apparel Industry Using Computer-Aided Design | C. Rajesh Kumar | Associate Professor, Department of Fashion Technology, Sona College of Technology, Salem |

| Academic Year (2022-23) | ||||

|---|---|---|---|---|

| S.No. | Date | Name of Event | Resource Person | Organization |

| 1 | 07.03.2023 | Innovation and Advancement in Garment Technology | Dr. T. Saravanakumar | Dev Info Tech, Karur |

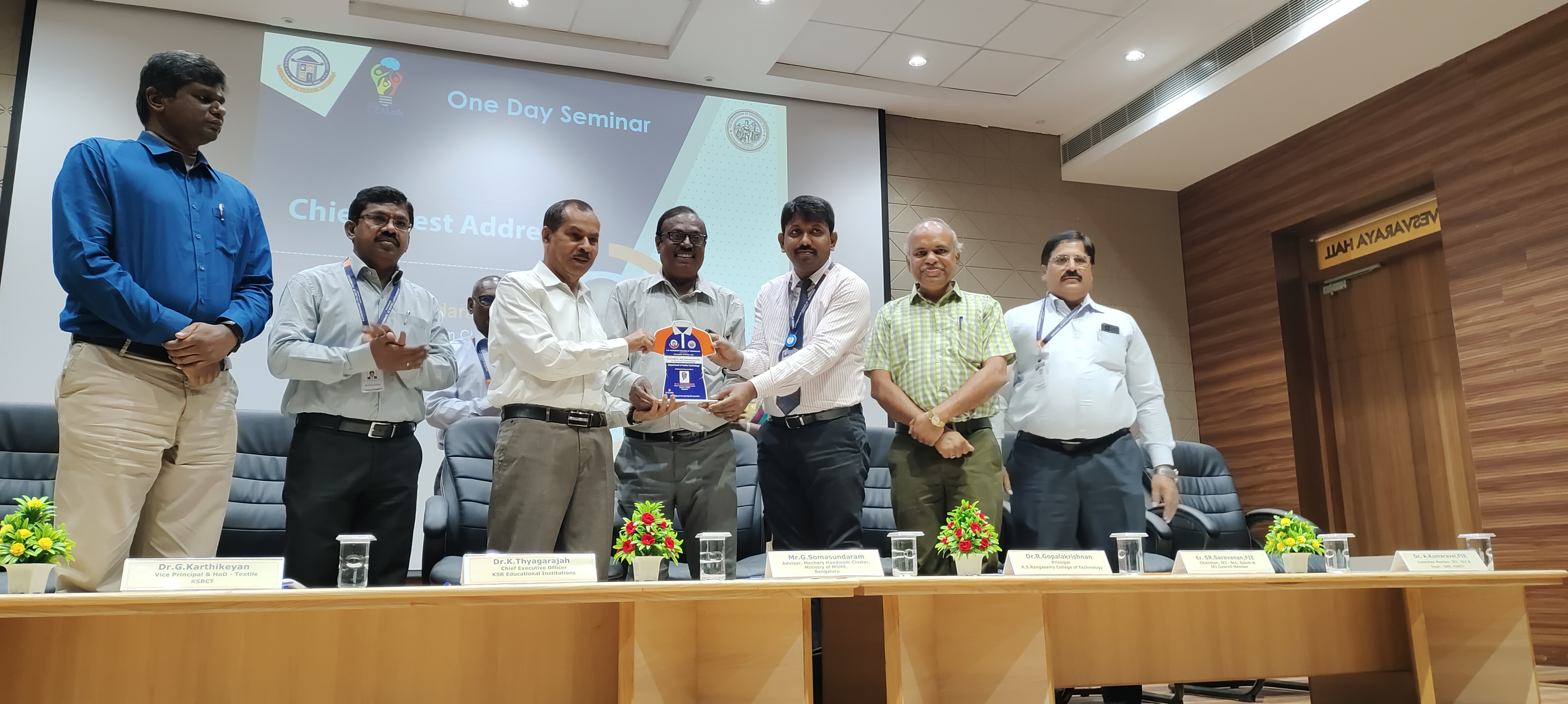

| 2 | 07.03.2023 | The Institution of Engineers (India) | Mr. G. Somasundaram | Advisor, Mechery Handloom Cluster - Ministry of MSME, Bengaluru |

| 3 | 07.03.2023 | The Institution of Engineers (India) | Mr. R. Sembulingam | Managing Director, Infinite Excellence LLP, Chennai |

| 4 | 07.03.2023 | The Institution of Engineers (India) | Mr. V. Sureshkumar | Raw Material Manager, PVH – Tommy Hilfiger North America, Bengaluru |

| 5 | 07.03.2023 | The Institution of Engineers (India) | Mr. N. Giridharan | Assistant Professor, Department of Artificial Intelligence and Data Science, K.S. Rangasamy College of Technology, Tiruchengode |

| 6 | 11.08.2022 | Enhancing Sales Through Branding and Marketing | Mrs. G. Kavitha | Branch Manager, Indian Bank, Bhavani |

| 7 | 23.07.2022 | Innovations in Physical Testing of Textile | Mr.K.Navaneethakrishnan | Quality Assurance, Jay Jay Mills Pvt Ltd., Perundurai |

| 8 | 19.07.2022 | Customer-Centric Marketing in Fashion Retail | Mr.G.Kaarthikeyan | Raymond Limited, Business Development Manager, South India |

Cells & Clubs

- Name of the Cells/Clubs: Join Hands Club

| S.NO. | Date | Event | Title of the Event |

|---|---|---|---|

| 1 | 18.11.2022 | Inaguration | Join Hands Club |

Achievements

with cash prize of Rs.5,000/- (TEXATHON -3.0) Received from AIC-NIFT TEA Incubation Centre, Tiruppur on March 18-19, 2025

Technology,salem.

Prizes

| Academic Year (2024-25) | |||||

|---|---|---|---|---|---|

| S.No. | Date | Name of The Student | Name of the Organizer | Name of the Event | Prize |

| 1 | 11.12.2024 | Sharmila M | Jaya Engineering College, Chennai | Fashion Design | I Prize |

| 2 | 11.12.2024 | Thulasimani V | Jaya Engineering College, Chennai | Fashion Design | III Prize |

| 3 | 11.12.2024 | Vasikaran V | Jaya Engineering College, Chennai | Fabric Draping | II Prize |

| 4 | 11.12.2024 | Shrnitha N.M | Jaya Engineering College, Chennai | Face Painting | I Prize |

| 5 | 11.12.2024 | Thillaiarasu U | Jaya Engineering College, Chennai | Face Painting | III Prize |

| 6 | 11.12.2024 | Thillaiarasu U | Jaya Engineering College, Chennai | Fashion Photography | II Prize |

| 7 | 27.11.2024 | Raghavendhar A.V | Sona College of Technology, Salem | Face Painting | III Prize |

| 8 | 27.11.2024 | Shanmugapriya K | Sona College of Technology, Salem | Tie and Dye | I Prize |

| 9 | 27.11.2024 | Subhalakshmi B | Sona College of Technology, Salem | Tie and Dye | II Prize |

| 10 | 27.11.2024 | Dhivyasri Y | Sona College of Technology, Salem | Identifying Weave Pattern | III Prize |

| 11 | 27.11.2024 | Saranyadevi J.V | Sona College of Technology, Salem | Identifying Weave Pattern | III Prize |

| 12 | 19.11.2024 | Ragupathi M | Kumaraguru College of Technology, Coimbatore | Toy Making from Waste Fabric | I Prize |

| 13 | 19.11.2024 | Munishwari S | Kumaraguru College of Technology, Coimbatore | Window Display | II Prize |

| 14 | 19.11.2024 | Rubanraj N | Kumaraguru College of Technology, Coimbatore | Toy Making from Waste Fabric | II Prize |

| 15 | 19.11.2024 | Shathya M | Kumaraguru College of Technology, Coimbatore | Identify Weave Pattern | II Prize |

| 16 | 19.11.2024 | Akshaya B.S | Kumaraguru College of Technology, Coimbatore | Identify Weave Pattern | III Prize |

| Academic Year (2023-24) | |||||

|---|---|---|---|---|---|

| S.No. | Date | Name of The Student | Name of the Organizer | Name of the Event | Prize |

| 1 | 15.05.2024 to 19.05.2024 | Sowndarya P.R | Ministry of Skill Development & Entrepreneurship, Government of India, New Delhi | India skills 2024 | State Winner & National Participation |

| 2 | 25.03.2024 | Sunmathi M | Vellore Institute of Fashion Technology, VIT, Chennai | TEX FASHION 24 FEST’24 Waste to Wealth | I Prize |

| 3 | 25.03.2024 | Dharun A | Vellore Institute of Fashion Technology, VIT, Chennai | TEX FASHION 24 Waste to Wealth | II Prize |

| 4 | 25.03.2024 | Varun S | Vellore Institute of Fashion Technology, VIT, Chennai | TEX FASHION 24 Waste to Wealth | II Prize |

| 5 | 25.03.2024 | Yuvaraj L | Vellore Institute of Fashion Technology, VIT, Chennai | TEX FASHION 24 Waste to Wealth | III Prize |

| 6 | 25.03.2024 | Yaswanth B | Vellore Institute of Fashion Technology, VIT, Chennai | TEX FASHION 24 Hand Designing | II Prize |

| 7 | 25.03.2024 | Akshaya B.S | Vellore Institute of Fashion Technology, VIT, Chennai | TEX FASHION 24 Hand Designing | II Prize |

| 8 | 25.03.2024 | Baskar S | Vellore Institute of Fashion Technology, VIT, Chennai | TEX FASHION 24 Hand Designing | III Prize |

| 9 | 25.03.2024 | Arjun R K | Vellore Institute of Fashion Technology, VIT, Chennai | TEX FASHION 24 Hand Designing | III Prize |

| 10 | 19.03.2024 | Abishek K S & Prasanth E | Kumaraguru College of Technology, Coimbatore | Tie & Dye | I Prize |

| 11 | 19.03.2024 | Gobinath K & Gokulavasan K | Kumaraguru College of Technology, Coimbatore | Identifying Machine Parts | II Prize |

| 12 | 09.03.2024 | Abu Syed Mubaraq | Anna University, Chennai | TEXTPLOSION & FESTITO’24 Weave Identification | II Prize |

| 13 | 09.03.2024 | Abishek K.S | Anna University, Chennai | TEXTPLOSION & FESTITO’24 Weave Identification | II Prize |

| 14 | 09.03.2024 | Thillaiarasu U | Anna University, Chennai | TEXTPLOSION & FESTITO’24 Fashion Photo Graphic | I Prize |

| 15 | 09.03.2024 | Sharnitha N M | Anna University, Chennai | TEXTPLOSION & FESTITO’24 Fashion Photo Graphic | III Prize |

| 16 | 09.03.2024 | Saravanan E | Anna University, Chennai | TEXTPLOSION & FESTITO’24 Fashion Tech Hackathon | II Prize |

| 17 | 09.03.2024 | Somasundaram N | Anna University, Chennai | TEXTPLOSION & FESTITO’24 Fashion Tech Hackathon | II Prize |

| 18 | 09.03.2024 | Harish D | Anna University, Chennai | TEXTPLOSION & FESTITO’24 Fashion Tech Hackathon | II Prize |

| 19 | 09.03.2024 | Kiruthikraja K | Anna University, Chennai | TEXTPLOSION & FESTITO’24 Paper Presentation | III Prize |

| 20 | 09.03.2024 | Nikhil Praveen | Anna University, Chennai | TEXTPLOSION & FESTITO’24 Paper Presentation | III Prize |

| 21 | 09.03.2024 | Gobinath K | Anna University, Chennai | TEXTPLOSION & FESTITO’24 Weave Identification | I Prize |

| 22 | 09.03.2024 | Gokulavasan K | Anna University, Chennai | TEXTPLOSION & FESTITO’24 Weave Identification | I Prize |

| 23 | 30.12.2023 | Shanmugapriya K | All India Level Karate Tournament, Namakkal | Puduvai Everest Martial Arts Academy | I Prize |

| Academic Year (2022-23) | |||||

|---|---|---|---|---|---|

| S.No. | Date | Name of The Student | Name of the Organizer | Name of the Event | Prize |

| 1 | 17.04.2023 | Obu Umamaheswari M | K S Rangasamy College of Technology, Tiruchengode | Project Exhibition Cum Contest 2023 | I Prize |

| 2 | 17.04.2023 | Moulidharan M | K S Rangasamy College of Technology, Tiruchengode | Project Exhibition Cum Contest 2023 | I Prize |

| 3 | 17.04.2023 | Santhosh P | K S Rangasamy College of Technology, Tiruchengode | Project Exhibition Cum Contest 2023 | II Prize |

| 4 | 17.04.2023 | Suganeswaran M | K S Rangasamy College of Technology, Tiruchengode | Project Exhibition Cum Contest 2023 | III Prize |

| 5 | 31.03.2023 | Prasanth S | Bon Secours Arts and Science College for Women, Namakkal | Chadar 2023 | I Prize |

| 6 | 31.03.2023 | Srinithi N | Bon Secours Arts and Science College for Women, Namakkal | Chadar 2023 | I Prize |

| 7 | 29.03.2023 | Sujeet S | Alagappa College of Technology, Chennai | Texplosion & Festido'23 | I Prize |

| 8 | 29.03.2023 | Arjun P | Alagappa College of Technology, Chennai | Texplosion & Festido'23 | II Prize |

| 9 | 29.03.2023 | Bharani M | Alagappa College of Technology, Chennai | Texplosion & Festido'23 | I Prize |

| 10 | 29.03.2023 | Jai Chandru B | Alagappa College of Technology, Chennai | Texplosion & Festido'23 | I Prize |

| 11 | 29.03.2023 | Sujeet S | Alagappa College of Technology, Chennai | Texplosion & Festido'23 | II Prize |

| 12 | 29.03.2023 | Indhira Kumar R | Alagappa College of Technology, Chennai | Texplosion & Festido'23 | I Prize |

| 13 | 29.03.2023 | Harini K | Alagappa College of Technology, Chennai | Texplosion & Festido'23 | I Prize |

| 14 | 29.03.2023 | Veeraragavan V | Alagappa College of Technology, Chennai | Texplosion & Festido'23 | II Prize |

| 15 | 29.03.2023 | Vinoth Kumar S | Alagappa College of Technology, Chennai | Texplosion & Festido'23 | II Prize |

| 16 | 29.03.2023 | Kiruthik Raja K | Alagappa College of Technology, Chennai | Texplosion & Festido'23 | III Prize |

| 17 | 29.03.2023 | Thakchanamoorthi M V | Alagappa College of Technology, Chennai | Texplosion & Festido'23 | III Prize |

| 18 | 29.03.2023 | Indhira Kumar R | Alagappa College of Technology, Chennai | Texplosion & Festido'23 | I Prize |

| 19 | 29.03.2023 | Harini K | Alagappa College of Technology, Chennai | Texplosion & Festido'23 | I Prize |

| 20 | 29.03.2023 | Vasikaran V | Alagappa College of Technology, Chennai | Texplosion & Festido'23 | II Prize |

| 21 | 29.03.2023 | Kiruthik Raja K | Alagappa College of Technology, Chennai | Texplosion & Festido'23 | II Prize |

| 22 | 29.03.2023 | Nikhil Pravin M | Alagappa College of Technology, Chennai | Texplosion & Festido'23 | II Prize |

| 23 | 29.03.2023 | Suryaprasanth R | Alagappa College of Technology, Chennai | Texplosion & Festido'23 | II Prize |

| 24 | 17.02.2023 | Ranjithkumar R | EIT Polytechnic College, Erode | Fashion Fest2k23 | II Prize |

| 25 | 17.02.2023 | Harini K | EIT Polytechnic College, Erode | Fashion Fest2k23 | II Prize |

| 26 | 17.02.2023 | Varunraj N | EIT Polytechnic College, Erode | Fashion Fest2k23 | Best Performance Award |

| 27 | 25.02.2023 | Yogesh R | Precision Rubber Industries Pvt. Ltd, Mumbai | Good Performance in the Textile Spinning Technology subjects | Precitex Award |

| 28 | 25.02.2023 | Guru Haran R | Precision Rubber Industries Pvt. Ltd, Mumbai | Good Performance in the Textile Spinning Technology subjects | Precitex Award |

| 29 | 25.02.2023 | Vasantha Kumar B | Nature Science Foundation, Coimbatore | Fifth Award Ceremony | Best College Student Award |

| 30 | 14.10.2022 | Gokul S | SSM College of Arts and Science, Komarapalayam | Fashionk22 Giltz | III Prize |

| 31 | 14.10.2022 | Hari I | SSM College of Arts and Science, Komarapalayam | Fashionk22 Giltz | III Prize |

Awards

| S.No. | Year | Name of the Student | Title Of the Contest | Project Title | Fund Received(₹) |

|---|---|---|---|---|---|

| 1 | 2024-25 | D. Harish, E. Saravanan | Bagathon 2024 | Development of Bag using fresh Selvedge waste | 100000 |

| 2 | 2024-25 | V. Gokuluvasan, V. Gopinath | ED-II Hackathon 2024 | Innovation Development for agriculture land | 100000 |

| 3 | 2024-25 | T. Harikrishnan, S. Hariprasath, G.M. Sethubharathi | Start-up TN 1.0 State level Hackathon | Investigation of Thermal Insulation and sound absorption properties of recycled non woven and development of automotive interiors. | 110000 |

| 4 | 2023-24 | M.P. Asmitha | MSME Idea Hackathon 3.0 | IoT Based Humidity Plant for Small Scale Textile Industries | 1475000 |

| 5 | 2023-24 | K. Manikandan, M. Suganeswaran | MSME Idea Hackathon 2.0 | Digital Shuttle Box for Power Loom Controlled by Mobile App | 1450000 |

| 6 | 2022-23 | S. Sathishkumar | Next Generation Hand Crafts Skill Competition 2022-23 | Hand Art Painting | 2000 |

| 7 | 2022-23 | V. Pasupathi, K. Poovarasan, S. Govindaraj | MSME Idea Hackathon 1.0 | Design and Fabrication of Nano Jacquard | 1450000 |

| 8 | 2022-23 | K. Manikandan, M. Suganeswaran | Student Project Scheme, Tamilnadu State Council for Science and Technology | Design and Development of IoT mobile application for controlling Shuttle box in Drop Box Power Loom | 7500 |

| 9 | 2022-23 | G. Bommu Saravan, S. Swathi | Student Project Scheme, Tamilnadu State Council for Science and Technology | Non-Toxic Bamboo-Goss Sanitary Napkin | 7500 |

| 10 | 2022-23 | S. Bharathkumar, R. Sabari Sree Aravind | Student Project Scheme, Tamilnadu State Council for Science and Technology | EMF Resistant Clothing | 7500 |

| Academic Year (2024-25) | ||||

|---|---|---|---|---|

| S.No. | Date of Visit | Number of Students Attended | Name of Industry | |

| 1 | 09.08.2024 | 53 | Indigo Fusion Pvt Ltd, Erode. | |

| 2 | 21.09.2024 | 53 | Best Colour Solutions India Pvt Ltd, Perundurai | |

| 3 | 04.10.2024 | 47 | WFB Baird & Company (India) Pvt. Ltd, Kerala. | |

| 4 | 25.10.2024 | 63 | Gainup Group of Companies, Dindigul. | |

| 5 | 23.11.2024 | 59 | Pallava Mills, Veppadai. | |

| Academic Year (2023-24) | ||||

| S.No. | Date of Visit | Number of Students Attended | Name of Industry | |

| 1 | 04.11.2023 | 44 | Sri Senthil Murugan Ginning Factory, Perundurai. | |

| 2 | 05.11.2023 | 44 | Majestic Exports, Tirupur. | |

| 3 | 02.12.2023 | 48 | Knit Fair, Tirupur. | |

| 4 | 20.01.2024 | 63 | Grey Field, Tirupur. | |

| 5 | 20.01.2024 | 63 | Vasa Nonwoven Limited, Avinashi. | |

| 6 | 09.02.2024 | 66 | Pallava Mills, Veppadai. | |

| 7 | 01.06.2024 | 43 | William Good Acre and Sons India Limited, Alaphuaza, Kerala. | |

| 8 | 01.06.2024 | 43 | Kerala Ballers, Alaphuaza, Kerala. | |

| 9 | 01.06.2024 | 43 | International Coir Museum, Alaphuaza, Kerala. | |

| Academic Year (2022-23) | ||||

| S.No. | Date of Visit | Number of Students Attended | Name of Industry | |

| 1 | 22.08.2022 | 24 | Shri Cheran Synthetics, Veppadai. | |

| 2 | 11.09.2022 | 71 | Pallava Mills, Veppadai. | |

| 3 | 22.10.2022 | 41 | SITRA, Coimbatore. | |

| 4 | 19.11.2022 | 66 | Arthanari Looms, Tiruchengode. | |

| 5 | 19.12.2022 | 66 | MAG Solvics Pvt Ltd, Coimbatore. | |

| 6 | 27.01.2023 | 65 | Sakthi Fabrics, Salem. | |

| 7 | 15.02.2023 | 63 | Jansons Industries Limited, Tiruchengode. | |

| 8 | 17.03.2023 | 66 | Texvalley, Erode. | |

EVENTS

Virtual Admissions Counsellor

© 2024 KSRCT. All Rights Reserved